Low-Maintenance Concrete Walkways in St. Louis Homes

Concrete Walkway St. Louis

Building a durable concrete walkway in clay soil regions requires specialized techniques addressing unique challenges that homeowners in St. Louis and throughout Missouri commonly face. Clay soils shrink dramatically during dry periods and swell considerably when wet, creating powerful forces that crack and displace poorly designed walkways. Understanding proper base preparation, drainage management, and reinforcement strategies ensures walkways remain level and intact through years of seasonal moisture fluctuations. Properties from Kirkwood to Florissant benefit from construction methods specifically adapted to expansive soils rather than generic approaches suitable for stable sandy or loamy conditions. Professional installation techniques, preventing common clay soil problems, deliver low-maintenance walkways that serve reliably for decades.

Understanding Clay Soil Challenges for Concrete Walkways

Clay soils are made of extremely small particles, smaller than .002 millimeters, that are packed tightly, giving them special characteristics in how they affect concrete construction. These soils can hold an enormous amount of water and expand dramatically with changes in the moisture level. As clay becomes saturated, it exerts incredible upward and outward pressures on concrete slabs. When clay dries out, it will contract and shrink and create voids underneath the walkways that lead to settling and cracking. The Missouri climate, which includes spring rains, summer heat and dryness, and freezing-thawing cycles, makes these clay challenges even worse. Homeowners in Webster Groves and Crestwood can anticipate clay behavior on their property and take measures to counteract potential problems prior to installing a concrete walkway.

Identifying Clay Soil on Your Property

Knowing what kind of soil you have is important to understanding the needs of your construction project. To identify clay soil, look for the “stickiness” and ability to be molded when wet, much like pottery clay. When clay dries, it creates a hard, concrete-like mass that is difficult to break apart. Water also tends to pool on clay soils rather than quickly draining. Deep cracking can be observed in clay soils during extended drought periods. Several simple field tests can be performed to determine soil types, such as the “ribbon test,” where if you squeeze a small amount of moist soil between your fingers and it forms long, thin ribbons, it indicates that the soil has a high clay content. Professional soil testing services in the areas of Maplewood and Brentwood offer detailed composition analyses that guide your construction decisions. Additionally, looking at existing concrete in your neighborhood that has been installed will give you an indication of how local soils affect the construction process, with widespread cracking or settlement indicating poor clay soils that require additional construction techniques.

Excavation and Base Preparation

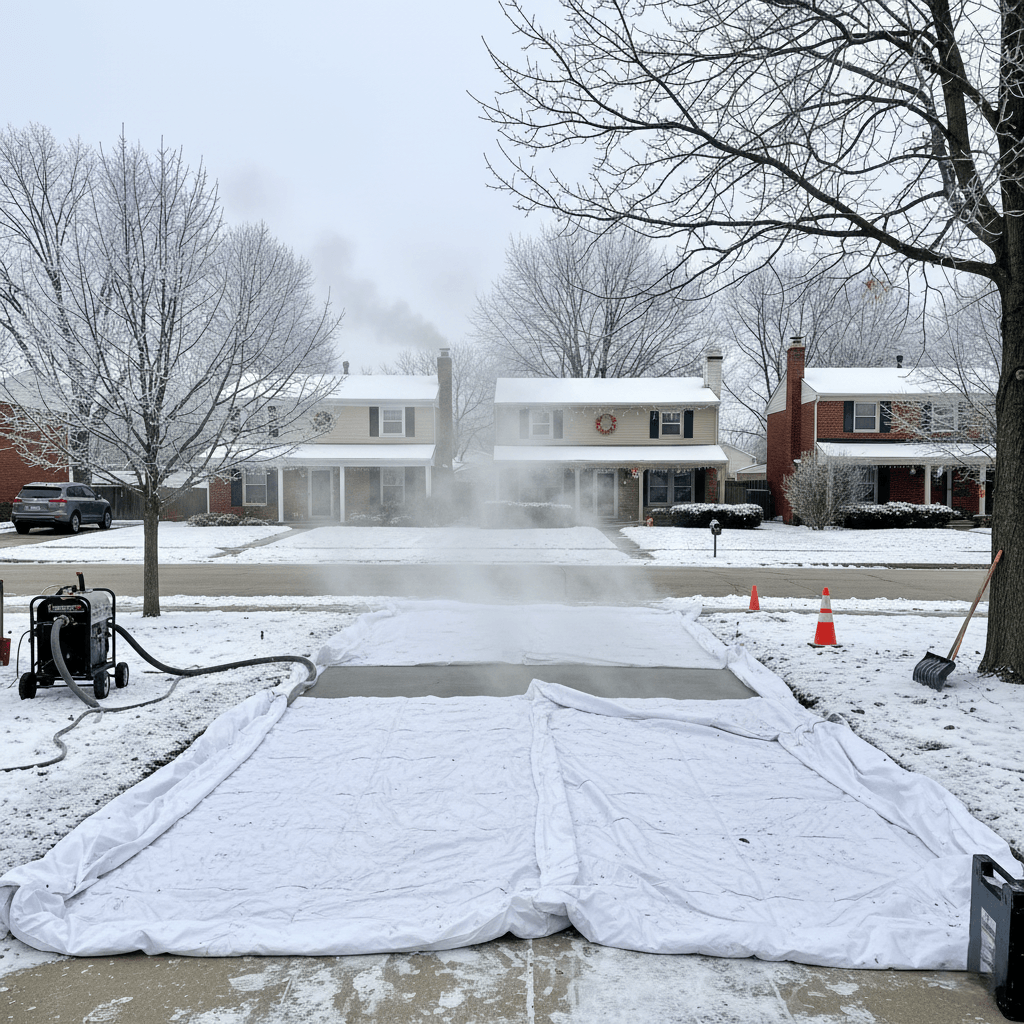

Excavation is the first step in constructing a successful concrete walkway in clay-soiled areas. A thorough excavation allows for sufficient room for base material and the desired thickness of concrete (typically 8-12 inches total depth for pedestrian walkways). All topsoil, vegetation, and organic matter need to be removed because, as they decay, they settle the clay subgrade. After excavation, the clay subgrade must be mechanically compacted using a plate compactor to reach the required density. Never compact clay when it is too wet, as this will trap moisture and create future problems. Excavation in clay soils should always be done in favorable weather when the clay is sufficiently moist to work with. Finally, installing a proper drainage slope in the excavation will help direct water away from the walkway, eliminating moisture accumulation under the slab that contributes to swelling cycles that can destroy the walkway.

Gravel Base Installation

A substantial gravel base is essential for concrete walkways constructed in clay soils. This base performs multiple beneficial functions for concrete walkways in clay soils. Install a crushed stone base material (4-8 inches thick) over the compacted clay subgrade. The gravel base acts as a drainage pathway to direct water away from the concrete and eliminate moisture accumulation in expansive clays. The gravel base also acts as a capillary break to reduce moisture migration upward into the concrete. The compacted gravel base will act as a stable platform of support to resist settlement caused by clay volume changes. Only use angular crushed stone as opposed to rounded river rock, as angular stone shapes interlock better during compaction. In areas of clay soils with exceptionally poor performance, it is recommended to install thicker gravel bases. In addition, a geotextile fabric applied between the clay and gravel will keep fine clay particles from migrating upward into the gravel layer, and thereby maintain its drainage function.

Integration of Drainage Systems

Drainage systems are crucial to the long-term performance of concrete walkways in clay soils. Properly graded walkway surfaces to slope away from buildings (typically 1/8 to 1/4 inch per foot) will direct water runoff away from the walkway. Installing the concrete walkway itself, slightly crowned (higher in the middle), will encourage water to run off the edges of the walkway instead of collecting in the center. Creating a drainage swale or channel along the walkway will capture and redirect water away from the clay soils under the walkway. Many homes in Chesterfield and Ballwin require supplemental drainage systems to handle heavy rainfall events. Maintaining relatively constant moisture levels in the clay soils through proper drainage will minimize destructive expansion and contraction cycles that damage concrete walkways, regardless of other construction quality measures.

Methods to Prevent Water From Saturating Clay Soils Beneath Walkways

Multiple methods work together to prevent water from saturating clay soils under walkways. The first method involves extending roof downspouts at least 6 to 10 feet from walkway edges, either using buried drain lines or splash blocks. The second method involves grading surrounding landscaping to direct surface water away from the walkway areas. The third method involves installing sprinkler heads so that they do not regularly soak the walkway edges. The fourth method involves installing permeable landscaping materials (such as mulch or gravel) in planting beds adjacent to walkways to improve drainage compared to bare clay soils. The fifth method involves monitoring the drainage systems and keeping them clear of debris to prevent water accumulation, which causes soil movement. The sixth method involves adjusting watering schedules during droughts to maintain some consistency in soil moisture levels, since extreme drying causes the most severe contraction and void creation under walkways, resulting in settlement and cracking.

Reinforcement Methods for Clay Soil Conditions

Using proper reinforcement will greatly enhance the ability of a concrete walkway to withstand the stresses caused by the movement of clay soils. Welded wire mesh or rebar grids should be used to add tensile strength to the walkway, as plain concrete does not have the same strength in this regard. It is best to place the reinforcement about one-third up from the bottom of the slab thickness, or about 1.5 to 2 inches from the surface of a 4-inch walkway. Fiber reinforcement added to the concrete will distribute micro-reinforcement throughout the entire slab. Controlling cracking by cutting or forming intentional weak points in the form of control joints will create cracks in the walkway at specified intervals rather than randomly occurring cracks. Typically, control joints are spaced at 4-foot intervals for 4-inch-thick walkways. Using a combination of the above reinforcement methods, walkways installed in areas with the worst clay soils will result in fewer cracks and longer-lasting performance.

Concrete Mix Design Selection

Selecting the right mix design for concrete will increase the durability and crack-resistance of the walkway. For walkway installations, specify a minimum of 3,000 psi compressive strength. Increasing the strength to 4,000 psi will provide further resistance to stresses caused by soil movement. Air entrainment will improve the durability of the concrete to freeze-thaw cycles, especially relevant to the Missouri climate. Consider using supplementary cementitious materials (SCMs), such as fly ash or slag, to improve the long-term performance of the concrete. Synthetic fibers added to the concrete will provide crack control throughout the entire length of the walkway. Working closely with the supplier of ready-mixed concrete will enable specification of a mix design tailored to address the unique challenges presented by clay soils in the St. Louis Metro Area. Ensuring the proper water-to-cement ratio is maintained during the placing operation is critical, as excessive water will weaken the concrete, while inadequate water will impede curing and ultimately compromise the performance of the concrete in adverse soil conditions.

Details of Construction Joints and Expansion Gaps

Constructing joints and expansion gaps to allow for the concrete to move minimizes the occurrence of random cracking in walkways constructed in clay soils. Dowels or keyways should be included in construction joints where the placement of concrete stops to transfer loads between sections and permit slight movement. Isolation joints separating walkways from buildings, walls, or other rigid structures use compressible fill materials to allow independent movement. By doing so, the force generated by the building foundation or structure cannot be transferred to the walkway. Control joints will intentionally weaken the concrete at predetermined intervals, creating cracks in the walkway in a linear fashion at specified points rather than randomly occurring cracks. The spacing, size, and material selection for construction joints should conform to standard practices for the industry, rather than relying on arbitrary determinations. In addition to controlling movement, sealing joints with flexible polyurethane or silicone caulk after curing will prevent water infiltration and allow for continued movement.

Dimensional Requirements for Thickness and Width

The dimensional requirements for concrete walkways represent a balance between the necessary structural demands and cost constraints. Residential walkways typically use a 4-inch thickness of concrete, which is sufficient for pedestrian traffic, provided the base materials were properly prepared. However, in clay soil regions, a 5 or 6-inch thickness may be warranted to provide additional mass and strength to resist soil movement stresses. Walkway widths of 3 to 4 feet provide a comfortable single-file path, while widths of 4 to 5 feet allow two individuals to walk side-by-side. Walkways wider than 6 feet may necessitate additional reinforcement or greater concrete thickness. The dimensions of walkways should be designed based on the intended use and expected traffic patterns of the walkway. By limiting the width of walkways, the overall cost will be minimized, and the likelihood of differential settlement and subsequent cracking will be reduced due to the lower surface area experiencing varying soil conditions that contribute to uneven support.

Correct Curing and Finishing Techniques

Achieving design strength and durability in concrete walkways depends on proper curing techniques. Maintaining adequate moisture and temperature for at least 7 days after placement, and ideally for 28 days, will provide optimal strength development. Applying curing compounds immediately after finishing will create moisture-retaining films on the surfaces of the walkway. Protecting the walkway from early drying with plastic sheeting or wet burlap will maintain the moisture during the curing period. Walking on the new concrete should be avoided for at least 24 to 48 hours to allow adequate initial strength development. Appropriate finishing techniques for walkways include broom finishing, which produces a textured surface that is slip-resistant for exterior applications. Protecting newly placed concrete from premature drying, particularly in hot or windy weather, will help to preserve the moisture in the concrete and prevent early degradation. Properties in Affton and Lemay can assist in preserving newly placed concrete by maintaining the correct curing environment.

Protective Sealants for Long-Term Performance

Proper protective sealants will significantly extend the lifespan of concrete walkways in clay soils by protecting the surfaces of the walkway from moisture penetration, freeze-thaw damage, and staining. Penetrating sealers should be applied to the walkway after 28 days of curing, once the concrete has fully cured. These products will penetrate into the pores of the concrete and provide internal water repellency without leaving a film on the surface of the walkway. Protective sealants should be reapplied to the walkway every 2 to 3 years to continue providing protection throughout the lifespan of the walkway. Sealants will be especially important in clay soils, where the prevention of water accumulation is the determining factor in the success or failure of the walkway. Properties in Des Peres and Town and Country can expect to see the deterioration rate of their walkways significantly reduced with the use of periodic sealing maintenance. Sealants will also prevent damage to the walkway from salt usage in winter ice removal.

Landscaping and Vegetation Management

Landscaping decisions around concrete walkways will significantly impact the long-term performance of the walkway in clay soils. Planting large trees within 10 to 15 feet of a walkway will result in the tree roots seeking moisture and eventually creating voids in the clay soils or exerting pressure directly on the concrete. Drought-tolerant plantings that require less supplemental watering, which saturate the clay soils, should be selected. Planting beds should be created with proper drainage to prevent water from accumulating near the walkway edges. The use of mulch or gravel in planting beds adjacent to walkways will provide improved drainage compared to the clay soil alone. Balancing aesthetics with the practical aspects of preserving the walkway will be beneficial for homeowners in Olivette and Overland. Seasonal watering schedule modifications during droughts will help to provide a relatively consistent moisture level in the clay soils, as sudden changes in moisture will result in more extreme stresses than gradual changes.

Maintenance Activities

Regular maintenance activities will help to preserve the functionality and appearance of the concrete walkway in clay soils. Cleaning the walkway annually with a pressure washer will remove accumulated dirt, algae, and stains. Regular inspections of joints and cracks will provide opportunities to seal any openings and prevent water from entering the base materials and underlying clay soils. Monitoring adjacent landscaping to ensure that drainage features remain operational and vegetation does not encroach on the walkway edges will also provide opportunities for maintenance. Carefully removing snow and ice with plastic shovels and calcium-based deicers will help to avoid damaging the concrete. Maintaining a regular maintenance schedule will help to prolong the lifespan of the walkway. Addressing minor problems proactively will also help to prevent small issues from becoming major repair problems, as the economics of proactive maintenance are generally superior to those of reactive repairs addressing advanced deterioration.

DIY vs. Professional Installation

Homeowners must decide whether a professional contractor or a DIY approach will best meet their needs for the concrete walkway project in clay soils. Professional contractors understand the local soil conditions and how to construct walkways to specifically address the challenges associated with those soils. Contractors also have access to specialized equipment, such as plate compactors and concrete finishing tools, and the experience to produce a quality finished product. Professional contractors also generally provide warranties for their work and typically complete projects promptly. While DIY projects can be accomplished at a lower cost than hiring a professional, DIY projects require a great deal of manual labor, specialized tools, and technical knowledge to accomplish. Areas of the St. Louis Metro Area with particularly poor clay soils will generally benefit from the expertise of a professional contractor to minimize costly errors.

At St. Louis Concrete Works, we have extensive experience in designing and constructing durable concrete walkways in Missouri’s clay soils using established techniques, including proper base preparation, integrated drainage systems, and reinforcement methods that result in low-maintenance walkways that effectively resist soil movement stresses and provide homeowners with long-lasting pedestrian surfaces despite challenging expansive soil conditions.