St. Louis Concrete Slab Costs: Sizes & Pricing Breakdown

Concrete Slab St. Louis

Understanding concrete slab pricing and appropriate dimensions helps St. Louis homeowners plan construction projects effectively and avoid costly surprises. Whether you’re building a garage foundation in Maryland Heights or installing a shed base in Fenton, knowing typical costs and standard sizes ensures realistic budgeting. Local factors, including soil conditions, climate considerations, and permit requirements, influence both design specifications and total investment. Professional contractors throughout the metro area adapt recommendations to Missouri’s clay-rich soils and freeze-thaw cycles. Accurate information about a concrete slab empowers property owners to make informed decisions, balancing functionality, durability, and budget constraints for residential and light commercial applications.

Average Concrete Slab Costs in St. Louis

The average cost to install a concrete slab in the St. Louis metropolitan region can range from $4 to $8 per sq ft (depending on the complexity of the job) for an average 30 by 30 foot slab (900 sq ft). Depending on the location, size, thickness, reinforcing requirements, and decorative options, the price of a project can vary greatly. The average cost for a 30 by 30 foot slab (900 sq ft) will be approximately $3,600 to $7,200 for a standard 4-inch-thick slab. Smaller jobs may have minimum contractor charges of $1,000 to $1,500, which can affect the cost per square foot.

Breakdown of Material and Labor Costs

Materials account for approximately 40% to 50% of the total project cost and include the cost of the ready-mix concrete. Ready-mix concrete currently costs anywhere from $150 to $180 per cu yd in the St. Louis Metropolitan Region. Approximately one cu yd will cover about 81 sq ft of slab at 4 inches deep. Labor accounts for approximately 50% to 60% of the total project cost and averages $2 to $3 per sq ft for a standard 4-inch slab. This includes all the labor required for site preparation (grinding, saw cutting, etc.), form construction, concrete placement, finishing (broom finish), and clean up. Many factors can cause a contractor to charge more money for their services (i.e., having specialized equipment, being experienced, etc.). In addition to the cost of labor and materials, the delivery fee for the ready-mix concrete is typically $50 to $150, depending on how far it has to travel from the batch plant. It would be best for homeowners in Wentzville and O’Fallon to consider these factors when establishing a budget for this type of project. Although there is some extra cost involved, the quality of the work performed will help ensure that it lasts for decades.

Standard Slab Thicknesses for Residential Applications

In general, the standard slab thickness used for residential applications is 4 inches. This is sufficient for most residential applications that do not involve heavy foot traffic or equipment. For example, a 4-inch slab is suitable for small patios, walkways, and shed bases. For residential driveways, however, a 6-inch slab is recommended because they are subjected to heavier loads (i.e., cars, trucks, etc.) and are subject to greater stress due to the weight of the vehicles. The additional 2 inches of thickness will provide the structural support required to withstand vehicle loads and will help prevent cracking. A slab thickness of 8 inches is typically required for commercial applications or for residential applications where heavy equipment is stored.

Effect of Slab Thickness on the Amount of Material Needed

As you would expect, increasing the thickness of your slab increases the amount of material needed to complete the project. A 4-inch slab will require approximately 1.23 cu yds of concrete per 100 sq ft. A 6-inch slab will require approximately 1.85 cu yds per 100 sq ft (a 50% increase). An 8-inch slab will require approximately 2.47 cu yds per 100 sq ft (a 100% increase). Based on these numbers, the estimated cost per sq ft for a 4-inch slab will be $6 to $8. The estimated cost per sq ft for a 6-inch slab will be $7 to $10. The estimated cost per sq ft for an 8-inch slab will be $9 to $12. Homeowners in Arnold and Imperial should take into consideration the structural requirements of the slab and compare them to their budget for the project. Typically, a professional contractor will make recommendations regarding the thickness of the slab that will meet the structural requirements of the slab based on the specific application and location of the slab. They will also make sure to minimize any unnecessary waste of materials.

Standard Slab Sizes for Common Residential Applications

Residential slab sizes are generally smaller and more predictable compared to commercial slab sizes. For example, a single-car garage will typically be 12 x 22 feet (264 sq ft). A two-car garage will be 20 x 22 feet (440 sq ft). A three-car garage will be 32 x 22 feet (704 sq ft). Small storage sheds will typically be 10 x 10 feet to 12 x 16 feet (100 to 192 sq ft). Workshops will typically be 20 x 30 feet (600 sq ft). Patios can vary greatly in size from small bistro-style patios that are 10 x 12 feet (120 sq ft) to large entertainment-style patios that are 20 x 30 feet (600 sq ft). When determining the size of a slab, homeowners in Affton and Lemay should consider the size of their yard, setback requirements, and their budget for the project.

Examples of the Cost of a Concrete Slab Based on Size

When comparing prices for different sizes of slabs, it can be helpful to look at examples of the cost of slabs of different sizes. For example, a 10 x 10 foot shed base with a thickness of 4 inches will cost between $400 and $800 to install. A 12 x 16-foot storage building base with a thickness of 4 inches will cost between $768 and $1,536 to install. A 20 x 20 foot garage or patio base with a thickness of 4 inches will cost between $1,600 and $3,200 to install. A 24 x 24 foot two-car garage base with a thickness of 4 inches will cost between $2,304 and $4,608 to install. A 30 x 30 foot base for larger applications with a thickness of 4 inches will cost between $3,600 and $7,200 to install. These prices are estimates for standard installations and do not include the cost of any decorative finishes or special features that may be required for certain applications. Homeowners throughout Festus and Pevely should add 15 to 30% to these estimates to reflect the cost of thicker slabs or challenging site conditions that may require extensive preparation work.

Reinforcement Options and Costs

Reinforcing a concrete slab with a grid of steel bars or wire mesh significantly improves the overall strength of the slab and reduces the likelihood of cracking. Wire mesh is the least expensive option available, costing between $0.35 and $0.75 per sq ft for materials and installation. Welded wire fabric is a type of wire mesh that is specifically designed for reinforcing concrete. Steel rebar is a stronger alternative to wire mesh, but it is also more expensive. Rebar costs between $1.40 and $3.00 per sq ft, depending on the size of the rebar and the pattern in which it is spaced. Fiberglass is another alternative to steel rebar and costs between $0.30 and $0.50 per sq ft. Fiberglass fibers are added to the concrete to provide additional crack resistance. Homeowners in Ballwin and Manchester should consult with a professional contractor to determine the most cost-effective method of reinforcement for their specific application.

Other Types of Foundation Enhancements

Several other types of materials can be incorporated into a concrete slab to improve its performance and longevity. A vapor barrier is a layer of plastic sheeting placed under the slab to prevent moisture from migrating from the ground into the slab. Vapor barriers cost between $0.50 and $1.00 per sq ft and are typically used in applications such as climate-controlled buildings. Styrofoam insulation is another type of material that can be placed under a slab to provide thermal protection for heated spaces. Styrofoam insulation costs between $1.50 and $3.50 per sq ft, depending on the thickness of the insulation. Gravel base courses are used to create a stable sub-grade for the slab and cost between $1.00 and $3.00 per sq ft. Thickened edges are used to create a transition zone between the slab and any adjacent walls. Thickened edges cost between $1.00 and $3.00 per sq ft for the entire perimeter. Homeowners throughout Cottleville and St. Peters should consult with a professional contractor to determine the most cost-effective methods of enhancing their slab.

Costs Associated with Site Preparation and Grading

All concrete slabs require a certain amount of preparation work prior to the placement of the concrete. Site preparation involves clearing and preparing the land where the slab will be located. Grading involves leveling the land to create a stable sub-grade for the slab. Site preparation and grading costs can range from $0.40 to $2.00 per sq ft, depending on the difficulty of the job. More extensive excavation may be required for slabs that will be built on uneven terrain. Excavation can cost anywhere from $3 to $8 per sq ft and includes the cost of disposing of the excavated dirt. Compacting the sub-grade after excavation is typically part of the contractor’s pricing for the project. Removing trees or roots and/or clearing debris from the site can cost anywhere from $200 to $1,000 or more, depending on the extent of the work. In rare cases, the homeowner may need to hire a geotechnical engineer to analyze the soil and provide recommendations for stabilization. Hiring a geotechnical engineer can cost anywhere from $500 to $1,500. Homeowners throughout Shrewsbury and Webster Groves who live in areas with difficult topography or poor drainage should plan on paying for some of these additional costs. Proper preparation for the slab will also save money in the long term by preventing settling and cracking that can lead to costly repairs down the road.

Drainage and Erosion Control

Missouri receives a lot of rain,n so a properly drained concrete slab is critical to prevent erosion and structural damage to the slab. Surface grading is the first step in draining a slab. Surface grading involves creating a slight slope to direct water away from the slab. French drains and swales are the next steps in draining a slab. French drains are underground pipes that collect and move groundwater away from the slab. French drains can cost anywhere from $10 to $50 per linear foot installed. Swales are shallow ditches that collect surface water and channel it away from the slab. Swales can cost anywhere from $5 to $15 per linear foot. Installindownspoutsts that direct water from roofs away from the slab can cost anywhere from $100 to $300. If a slab does not drain properly, it will eventually settle and crack. Homeowners in Florissant and Hazelwood who address drainage in the early stages of their project will save themselves a lot of headaches later on. A professional contractor will assess the existing drainage conditions around a property and design a system that will manage the water in a way that will ensure long-term stability regardless of what the weather brings.

Decorative Options and Premium Finishes

While a standard broom-finished concrete slab is attractive and functional, there are a variety of ways to upgrade the aesthetic appeal of a slab. Stamped concrete is a popular way to upgrade the appearance of a slab by stamping it to resemble stone, brick, or other decorative materials. Stamped concrete can cost anywhere from $8 to $19 per sq ft, depending on the design and color selected. Acid staining is another way to upgrade the appearance of a slab by applying acid to the surface of the slab to create a marbled effect. Acid staining can cost anywhere from $3 to $15 per sq f,t depending on the colors selected. Integrated color can be added to the concrete during mixing to create a uniform color throughout the slab.

Integrated color can cost anywhere from $0.50 to $2.00 per sq, ft depending on the color selected. Exposed aggregate is a third option to create a decorative appearance on a slab by exposing the decorative rock embedded in the surface of the slab. Exposed aggregate can cost anywhere from $2 to $3 per sq ft. Polished finishes can be applied to interior slabs to create a glossy finish. The cost of polished finishes can vary greatly depending on the desired level of polish and can cost anywhere from $3 to $15 per sq ft. Homeowners throughout Clayton and Ladue are looking to upgrade the aesthetic appeal of their slabs while keeping their budget in mind. Most concrete contractors will provide samples of the different techniques mentioned above to assist in making a decision.

Sealing and Protective Treatments

Applying a sealer to a concrete slab will protect it from moisture, stains, and freeze-thaw damage. Basic acrylic sealers can cost anywhere from $1 to $2 per sq ft to apply. Penetrating sealers are a second option that can cost anywhere from $2 to $3 per sq ft. Epoxy coatings are a third option that can cost anywhere from $4 to $10 per sq ft. All three options will provide excellent protection for the slab. Sealers should be reapplied every 3 to 5 years to maintain the protection provided by the previous application. Homeowners throughout University City and Richmond Heights who invest in high-quality sealers will save money in the long term by reducing the need for repairs and replacements.

Permits and Building Codes

There are a variety of permits and regulations that will affect the cost and timeline of a concrete slab project. The City of St. Louis requires permits for almost all permanent structures. The cost of these permits varies depending on the scope of the project, but typically ranges from $50 to $200. St. Louis County has similar regulations and permit requirements, although the cost of the permits varies by municipality. After the slab is completed, a series of inspections will be conducted by the local authorities to ensure that the slab meets the minimum building code requirements for depth, reinforcement, and drainage. There may be setbacks in place that restrict the minimum distance that the slab can be constructed from the property lines. Homeowners throughout Chesterfield and Town and Country should check with their local government to determine if there are any building codes or regulations that may affect their project.

Code Compliance and Professional Guidance

The building codes provide the minimum standards that ensure the structural integrity and safety of a concrete slab installation. In Missouri, the typical frost depth is used to determine how deep (typically 30 to 36 inches) a footing needs to extend to protect against frost damage. Footings must be designed and engineered properly to support loads placed upon them. The drainage provisions included in the building codes are intended to prevent water from accumulating on top of the slab and forming ice. Licensed contractors who have knowledge of local building codes can easily comply with these requirements by obtaining all necessary permits prior to starting construction and by having their work inspected at the appropriate time.

For property owners in Wildwood and Ellisville, utilizing licensed contractors’ professional services will assist in eliminating the possibility of building code violations. In addition, installing a slab according to building codes will avoid possible future problems when you decide to remodel, refinance,nce or sell your home; since, if an inspector discovers unpermitted work during the inspection process, it could create delays and potential liability for the property owner to incur additional expense for retroactive compliance measures.

Seasonal Timing and Weather Factors

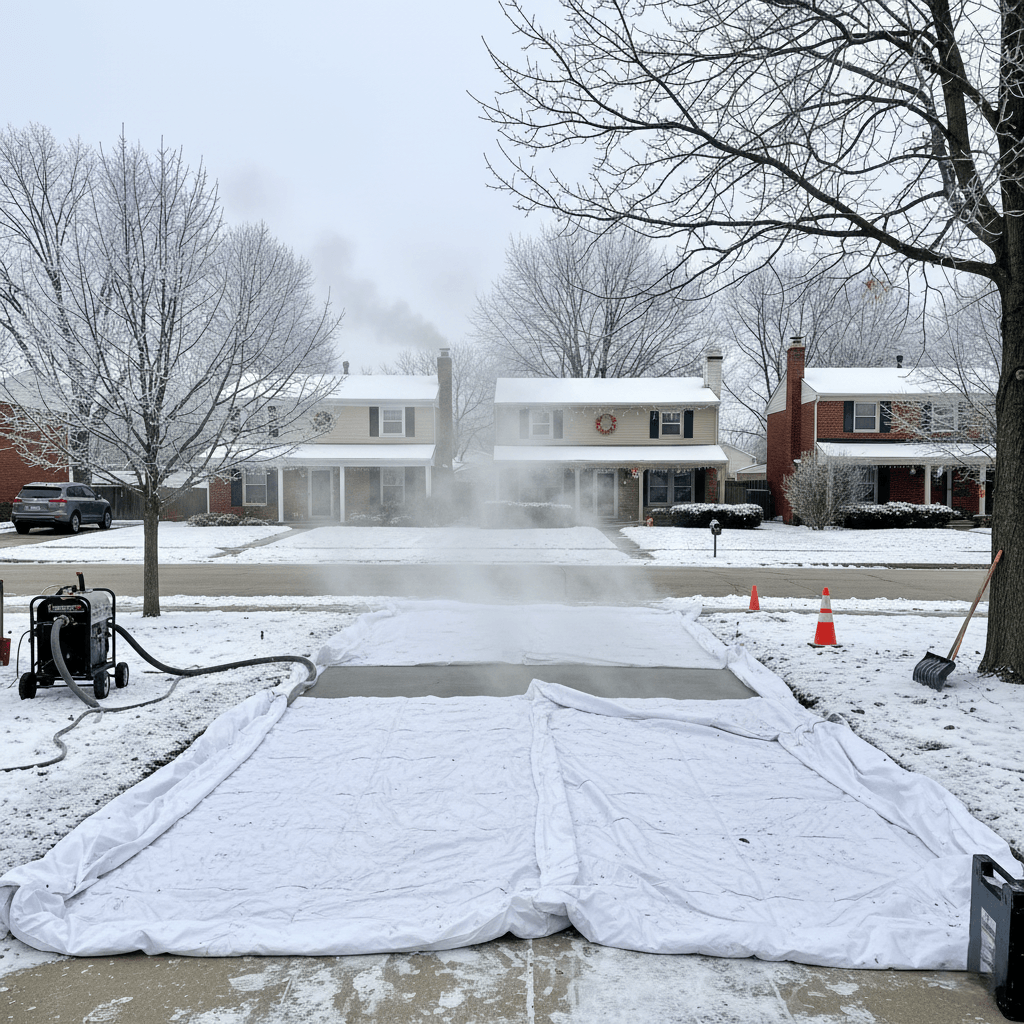

In Missouri, the ideal times for completing a concrete slab installation project are based on its climate. The ideal time to complete a concrete slab installation project would be during the spring and fall periods of the year when temperatures are moderate and precipitation is less likely. During the summer, high temperatures require special curing techniques to be employed to minimize moisture loss due to evaporation, although, generally speaking, the consistent weather allows for good working conditions. In the winter, the low temperatures limit the amount of time available for the completion of the concrete slab installation, because, typically, the concrete has to cure in above-freezing temperatures.

When necessary, contractors can include cold-weather admixtures in the concrete mix, which increases the cost slightly. Rainfall can delay a contractor’s schedule and also affect the quality of the finished product if the concrete becomes wet during the finishing process. Property owners in the Maryland Heights and Bridgeton areas of the St. Louis Metro area should expect some flexibility in their project timelines due to inclement weather. Additionally, contractors tend to be busier during the spring and fall seasons and may charge higher prices during those seasons, but they may also provide discounts during the winter months when there is less demand for their services.

16-foot

Long-Term Performance and Maintenance

A properly installed concrete slab can last up to 30 to 40 years with regular maintenance; however, some concrete slabs can exceed 100 years if maintained properly. Cleaning a concrete slab regularly will help to eliminate stains and prevent degradation of the surface. A protective sealant applied every 3 to 5 years will help to prevent moisture and stains from penetrating into the concrete and will also prevent freeze-thaw damage. Prompt attention to small cracks in the concrete will help to prevent water from entering the cracks and causing further damage. Proper drainage around the perimeter of the concrete slab will help to prevent the soil beneath the slab from eroding and settling. Property owners within the St. Louis Metro area are following the recommended maintenance guidelines to achieve the greatest return on their investments over several decades of reliable service.

At St. Louis Concrete Works, we design and install quality concrete slab foundations for residential applications throughout the region, combining appropriate materials, proper construction techniques, and attention to local soil and climate conditions, delivering durable installations that serve homeowners reliably for generations while meeting all applicable building codes and performance standards.