Pouring Concrete in St. Louis Winter: Precautions

Pouring Concrete St. Louis

In the winter in St. Louis, the temperature can be below freezing on a regular basis, which makes it very difficult to pour concrete. When pouring concrete during the cold weather months, it is necessary to have a plan in place for the work, as well as the appropriate tool,s and to follow the temperature guidelines. By understanding how to properly protect yourself and your investment, you are ensuring that the structural integrity of your project will last. When you are installing a driveway near Tower Grove Park or when you are replacing a patio in the Central West End, there is no better time than now to do the job right and to do the job with the proper cold-weather procedures.

Understanding St. Louis Cold Weather Issues

St. Louis has very cold weather during the winter months, with average temperatures ranging from 25°F to 40°F from December through February. These temperatures meet the American Concrete Institute’s (ACI) criteria for cold weather, as they state “cold weather” shall mean any period of three consecutive calendar days where the average daily temperature is below 40°F, or any period when the average daily temperature is below 50°F for more than one-half of any 24 hours. In addition, the city’s proximity to the Mississippi River causes higher humidity and wind-chill factors, which contribute to increased heat loss from newly poured concrete.

Important Temperature Factors for Construction

Ideal Temperature Range

Experts generally agree that the best temperature for pouring concrete is between 50°F and 60°F. Unfortunately, cold-weather construction usually means construction will take place in much colder temperatures. As temperatures decrease below 40°F, the chemical reactions that make concrete stronger occur at a slower rate, and may ultimately affect the final strength of the concrete. Freezing temperatures are worse still, because water in the mix can freeze and expand, causing both internal and external damage to the concrete.

Proper Curing Temperatures

Curing of concrete requires constant heat for at least 48 hours after placement. The ideal temperature during this curing period would be 50°F or warmer. Ideally, the total curing period of approximately seven days would have temperatures between 50°F and 70°F. Since the ambient air temperature does not represent the temperature of the concrete mass, monitoring of concrete temperature is very important when constructing in winter.

Preparation Before Pouring

Thawing Frozen Ground

It is never acceptable practice to pour concrete over frozen ground, as soil heaves when frozen and settles as it thaws, which creates many potential problems, including the removal of heat from the new concrete and premature cooling of the slab. Therefore, before any winter construction, particularly in areas like Lafayette Square, the contractor must thaw all of the ground in the area being prepared for concrete placement. Many contractors use portable thawing units to prepare the ground so that it will reach a temperature above 32°F. This will help prevent the concrete from cooling to a point below the critical 40°F during the placement process.

Storage of Materials and Heat

All materials required to make concrete should be stored in a warm, dry area prior to being mixed. All aggregate materials should be protected from snow and ice accumulation to keep them from lowering the temperature of the mix. Hot water should also be added to the mix to help raise the temperature of the concrete. The ideal temperature of the water is 140°F to 180°F. However, if the water is too hot or the materials are improperly handled, it could create a “flash set” condition, which is an irreversible, rapid hardening of the cement.

Modified Mix Designs for Winter

Modified mix designs for cold-weather concrete construction can be used to speed up the curing process. High Early Strength Cement, Type III, generates more heat during hydration than regular cement and can achieve strength faster than regular cements. Calcium chloride, a chemical accelerator, can be added to the mix to help speed up the curing process. However, the amount of calcium chloride added to the mix must be carefully measured and only used by qualified individuals.

Protective Measures During Curing

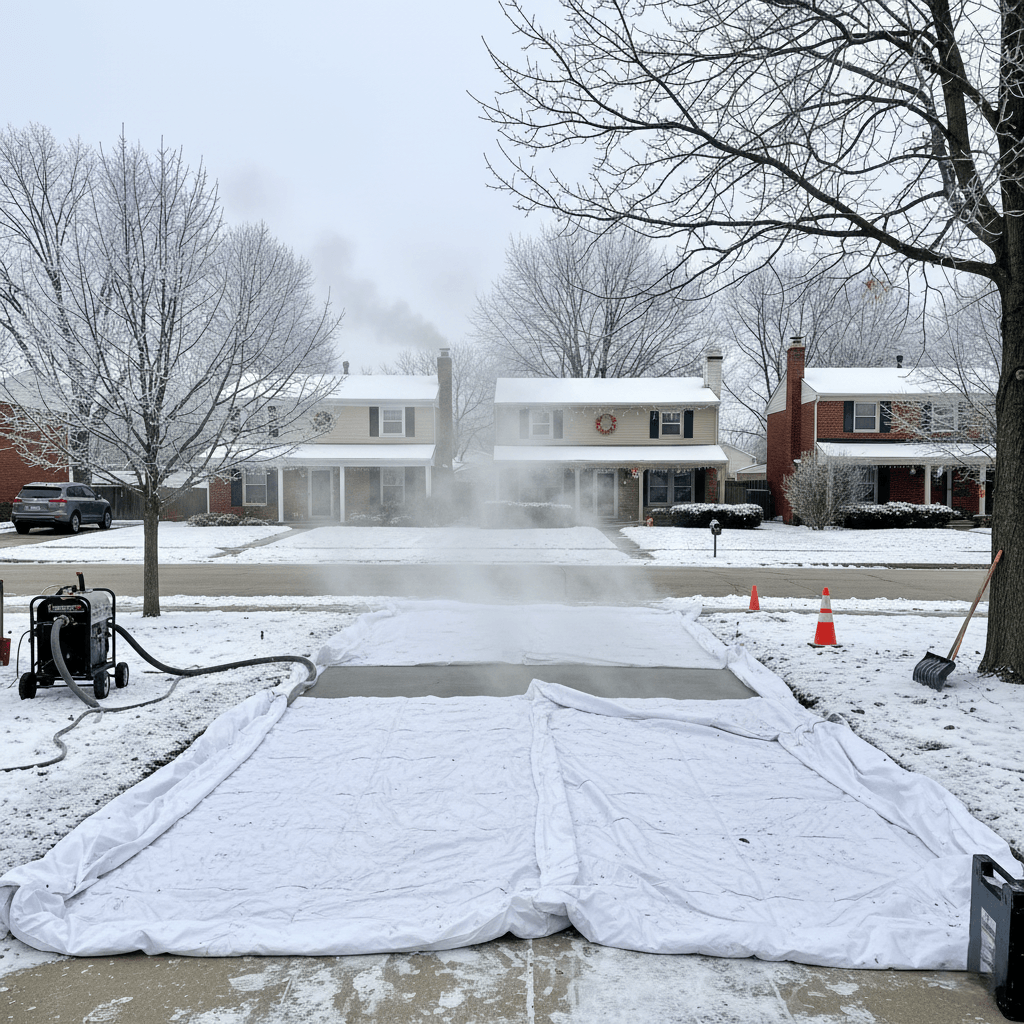

Blankets Insulating Concrete

Insulating concrete blankets are the best way to protect the concrete during the critical curing phase. These blankets trap the heat generated by the hydration of the concrete and maintain the optimal temperature, even when the ambient conditions are poor. Depending upon how cold the temperatures get, multiple layers of blankets may be needed. Also, the blankets must go past the edge of the concrete to prevent cold air from getting into the blanket and cooling the concrete.

Heated Enclosures and Windbreakers

When the temperatures are extremely low, using a heated enclosure will provide a controlled atmosphere for the concrete to cure. A heated enclosure will protect the concrete from the wind, which can greatly increase heat loss from the concrete due to convection. While using a windbreaker made from a tarp or plywood may not be as effective as a heated enclosure, it can still help improve curing conditions. It is also important to provide good ventilation in a heated enclosure to prevent carbon monoxide poisoning from the generators used to heat the enclosure.

St. Louis Building Code Requirements

The City of St. Louis Building Division requires permits for most concrete installations, which can be obtained through their One-Stop-Shop program. When applying for a permit, applicants must submit five copies of the plans and drawings for review by a design professional. Review will either be done on the same day or routed out, depending on the complexity of the project. Regardless of whether it is winter or summer, inspections will be scheduled based on the building code; however, there are some specific considerations regarding temperature monitoring when performing winter pours. Permits require 24 hours’ notice to the inspection section prior to commencing the placement of the concrete, and no concrete may be placed until a satisfactory soil inspection has been completed.

Required Inspection Points

Before placing concrete, inspections must be performed to confirm that the soil conditions have met the standards of the building code. An inspector will verify that the ground has been excavated and that the trenches for the footings have been dug and inspected. Once the inspector verifies the soil conditions, he will allow the placement of concrete. Inspectors must also inspect the forms for the foundation and the reinforcing steel prior to any concrete being placed. By requiring these inspections, the Building Division protects homeowners in neighborhoods such as Benton Park and Shaw by ensuring that the structure is sound.

Care of Post-pour Concrete

Once the concrete has been placed, the temperature of the concrete must continue to be monitored. The monitoring of the temperature will help ensure that the concrete continues to cure properly for the next 48 hours. A digital thermometer can provide continuous reading of the temperature of the concrete. If the temperature of the concrete falls below a safe level, additional heating methods must be applied to the concrete immediately. Any standing water on the surface of the concrete must be removed to prevent freezing damage and surface defects.

Common Mistakes of Winter Concrete

Many problems with concrete construction occur from rushing the process, and/or underestimating the effects of cold weather. Removing the protective blankets too soon will subject the concrete to thermal shock and possibly crack the surface of the concrete. De-icing salt must never be used on new concrete, as it will rapidly deteriorate the surface of the concrete. Failure to provide wind protection to the curing concrete will allow the concrete to cool convectively and will compromise the curing process. Understanding these common mistakes will help eliminate expensive repairs and produce longer-lasting results.

Experience Is Key to Success

Only experienced personnel and proper equipment will guarantee the successful management of cold-weather concrete construction. At St. Louis Concrete Works, we recognize the unique challenges that the winters of Missouri impose on construction projects. We monitor local weather forecasts, store our materials in heated areas, and implement proven protection methods to ensure each of our customers’ concrete achieves its full strength, regardless of the season. We offer a wide variety of services related to the installation of concrete, including residential driveways, commercial foundations, etc., and we do it all with a commitment to reliability and customer satisfaction in the St. Louis Metropolitan Area, regardless of the time of year.