How to Estimate Costs for Commercial Concrete in St. Louis, MO

Commercial Concrete St. Louis

Accurate cost estimation forms the foundation of successful commercial concrete projects throughout St. Louis. Business owners, developers, and contractors require a comprehensive understanding of pricing factors to budget effectively and avoid unexpected expenses. From warehouse floors in industrial corridors to parking structures downtown, commercial concrete installations demand precise financial planning. Material costs, labor rates, permit requirements, and project complexity all influence final expenditures significantly. Understanding how these variables interact within the St. Louis market enables informed decision-making and protects project budgets from costly surprises.

Understanding Base Material Costs

St. Louis commercial concrete suppliers price their products based on the amount of ready-mix concrete needed, expressed in cubic yards. Suppliers in the St. Louis metropolitan area charge between $150 and $180 per cubic yard of concrete, which varies depending on the type of mix (or combination of mixes) and the supplier’s delivery policies. Suppliers who charge less will likely have lower-strength mixes that do not contain admixtures (chemical additives), or they will have more expensive delivery options.

Estimating the Amount of Concrete Needed

To avoid running out of concrete for a job and having to pay for excess material, an estimator must calculate the correct amount of concrete needed. To estimate the number of cubic yards of concrete needed, you must multiply the length, width, and thickness of the area you want to pour, then divide by 27 (the number of cubic feet in a cubic yard). For example, to determine how much concrete is needed for a 100-foot x 200-foot warehouse floor that is 6 inches thick, you would calculate it as follows:

- Length = 100 ft.

- Width = 200 ft.

- Thickness = 0.50 ft.

- Area = Length x Width = 20,000 sq. ft.

- Volume = Area x Thickness = 10,000 cu. ft.

- Cubic Yards = Volume / 27 = 370 cy.

For small commercial jobs, the estimator will often include an extra 5% to 10% in the estimate to account for possible spills, uneven areas where the concrete was poured too quickly, and other variables that can affect the total amount of concrete used. When ordering concrete for larger commercial jobs, the contractor will usually order enough to fill one or more trucks. Ordering anything less than a full truckload of concrete can result in an additional fee charged by the supplier.

Specialty Mixes

Each application of commercial concrete has its own particular characteristics that require a different type of concrete mix. These different types of mixes will significantly affect the price of each cubic yard of concrete. There are many types of specialty mixes available to address the various needs of commercial clients.

Standard commercial concrete with 3,000 pounds per square inch (PSI) compressive strength is acceptable for most commercial applications, such as sidewalks and light-load slabs. However, there are some applications that require much stronger mixes, such as an industrial floor that supports very heavy machinery, which will require a mix with a compressive strength of 4,000 to 5,000 psi. The cost of this stronger mix will be 15% to 30% higher than the cost of a standard mix.

Fiber-reinforced mixes can help to prevent cracks and improve the overall durability of the concrete. They are especially useful for large slab placements, as they help to distribute tension forces within the concrete evenly. While fiber-reinforced mixes are slightly more expensive than standard mixes, they offer long-term benefits to commercial clients by extending the life expectancy of the concrete and providing a smooth, crack-free surface.

Air-entrained mixes are essential for preventing damage caused by freezing temperatures in the Midwest. While air-entraining agents add a modest amount to the cost of the concrete, they help to prevent damage that would otherwise result from freeze-thaw cycles.

Admixtures

There are also various admixtures that can be added to the concrete to perform a variety of functions. Examples of these functions include setting the rate of the concrete’s hydration process, modifying the consistency of the concrete, providing color, and providing special chemical properties. Depending on the function of the admixture, the cost can vary widely. Admixtures should be included in the estimate only after consulting with the supplier or manufacturer to ensure that they are compatible with the other ingredients in the concrete mix.

Estimating Labor Costs

Labor costs are estimated to comprise 30% to 50% of the total cost of a commercial concrete project. In the St. Louis area, labor costs for commercial concrete projects average between $2 and $4 per square foot, depending on the complexity of the job. More complex jobs, such as those with multiple elevations, intricate formwork, or decorative finishes, require more labor hours and, therefore, cost more.

Union Labor

The use of union labor in the St. Louis metropolitan area affects pricing, particularly for larger commercial projects. Skilled crews working under union contracts command higher wages; however, they tend to be more efficient, produce higher-quality work, and are less prone to callbacks and warranty claims.

Estimating Crew Size and Timeline

The size of the crew and the timeline for completing a job depend largely on the size of the project. Small commercial projects that can accommodate one truck placement at a time can be performed with a crew of three to five people. Large warehouse floors or multi-story parking garages require larger crews to coordinate the placement of multiple trucks of concrete. Additionally, rush jobs requiring overtime or weekend work can increase labor costs 25% to 50% beyond normal rates.

Weather Delays

Weather delays are common in St. Louis during the winter months, causing indirect labor costs due to crew downtime and delayed schedules.

Specialized Labor

Some commercial applications require specialized skills that command higher labor costs. For example, laser-guided screed operations to achieve very high levels of flatness for warehouse racking systems require specialized training. Similarly, decorative concrete applications, such as stamping, staining, or polishing, require artisan-level craftspeople.

Specialized Equipment

Operating specialized equipment, such as concrete pumps, increases both equipment rental costs and operator fees.

Quality Finishing Work

Quality finishing work distinguishes superior concrete installations from inferior ones, making the investment worthwhile to justify premium labor costs.

Site Preparation Costs

Accurate site preparation is crucial to the long-term success of a commercial concrete project and represents a significant cost component that is commonly underestimated by estimators at the onset of a project. The excavation and grading required for a site will vary greatly depending upon the existing conditions and the final grade of the site. Soil removal costs typically range from $2 to $5 per cubic yard, depending upon the distance to be hauled and the disposal fees associated with removing the dirt. Compacted aggregate base layers placed below a concrete slab to create a stable support layer for the slab typically cost between $1 and $3 per square foot.

Poor Subgrade Conditions

Poor subgrade conditions requiring soil stabilization or additional fill materials can increase site preparation costs significantly.

Utility Relocation Costs

Many commercial projects involve the relocation of underground utilities prior to the placement of concrete. Identifying the location of underground utilities requires professional locating services. Conflicts with underground utilities discovered during excavation will generate change orders and schedule delays unless addressed during the planning phase. Coordinating with utility companies for temporary shutdowns or permanent relocations will also add administrative time and potential connection fees to the project. It is essential to consider utility relocation costs during the estimation phase to avoid cost overruns due to unanticipated conflicts.

Reinforcement Material Costs

Steel reinforcement is added to concrete to resist tensile stresses and to distribute loads uniformly across a slab. The cost of reinforcing steel can vary greatly, depending on the size of the bars, the spacing of the bars, and the degree of difficulty involved in placing them in the concrete. Typically, the cost of reinforcing steel will range from $1 to $3 per square foot of slab area. Less expensive alternative reinforcement materials, such as welded wire mesh, are suitable for lighter-load applications. Fiber-reinforced polymers (FRP) that combine synthetic or steel fibers into the concrete matrix eliminate the need for separate labor to place the fibers and provide excellent crack control. Large commercial projects that require engineered reinforcement designs to support heavy loads or large unsupported spans will have significantly higher material costs.

Post-Tensioning Systems

Post-tensioning is a technique used to install cables within the concrete to provide additional compression and to prevent cracking. This method reduces the thickness of the concrete slab and provides better long-term durability. The cost of post-tensioning systems typically ranges from $4 to $8 per square foot, depending on the type of system selected and the amount of concrete required to complete the job. Post-tensioning is especially beneficial for elevated slabs and large column-free spaces, as it allows for thinner slabs and provides a more uniform surface.

Permitting Fees

Permits for commercial concrete work can range from a few hundred to thousands of dollars, depending on the size and complexity of the job. The City of St. Louis Building Division reviews and approves all commercial concrete plans and estimates to ensure compliance with the city building codes. The cost of permits is generally a percentage of the total cost of the project. Larger projects will generally have higher permit fees. Expedited plan review service is available for commercial concrete projects that qualify through the Business Assistance Center in the City of St. Louis. Review times for commercial concrete projects can range from immediate approval for simple projects to several weeks for projects with more complicated details.

Inspections

Commercial concrete work requires multiple inspections at key points in the construction process. Before the placement of concrete, an inspector will visit the site to verify that the soil and subgrade conditions are suitable to bear the weight of the concrete. Once the concrete is in place, inspectors will examine the placement of the rebar and the forms to ensure compliance with the approved plans. Finally, inspectors will review the finished product to ensure that it meets the applicable building codes. If any defects are found during the inspection process, the contractor will be required to repair the defective work, which can cause project delays and additional costs. Therefore, proper scheduling of inspections is essential to maintaining project momentum and minimizing potential disputes.

Code Compliance

In addition to complying with local building codes, commercial concrete projects must also comply with the relevant sections of the 2018 International Building Code. The IBC specifies the minimum requirements for the design, fabrication, and installation of structural reinforced concrete, including concrete mix designs and the testing of those mix designs. The IBC also addresses issues related to the placement of concrete, including the requirements for proper compaction, finishing, and curing. Projects located in designated historic districts must obtain approval from the City of St. Louis Cultural Resources Office, which verifies that the proposed project is consistent with the character of the historic district. Failure to comply with applicable codes and regulations will result in fines, penalties, and potential litigation.

Delivery and Rental Fees

Delivery fees for concrete can vary depending on the distance from the batch plant to the job site. Concrete delivered outside the supplier’s regular delivery zone may incur an additional fee. In addition to delivery fees, rental fees for specialized equipment, such as concrete pumps, laser screeds, and vibrators, must be factored into the estimate. Rental fees are generally charged on a daily basis. Equipment operators are also subject to hourly fees, which may be in addition to the rental fee.

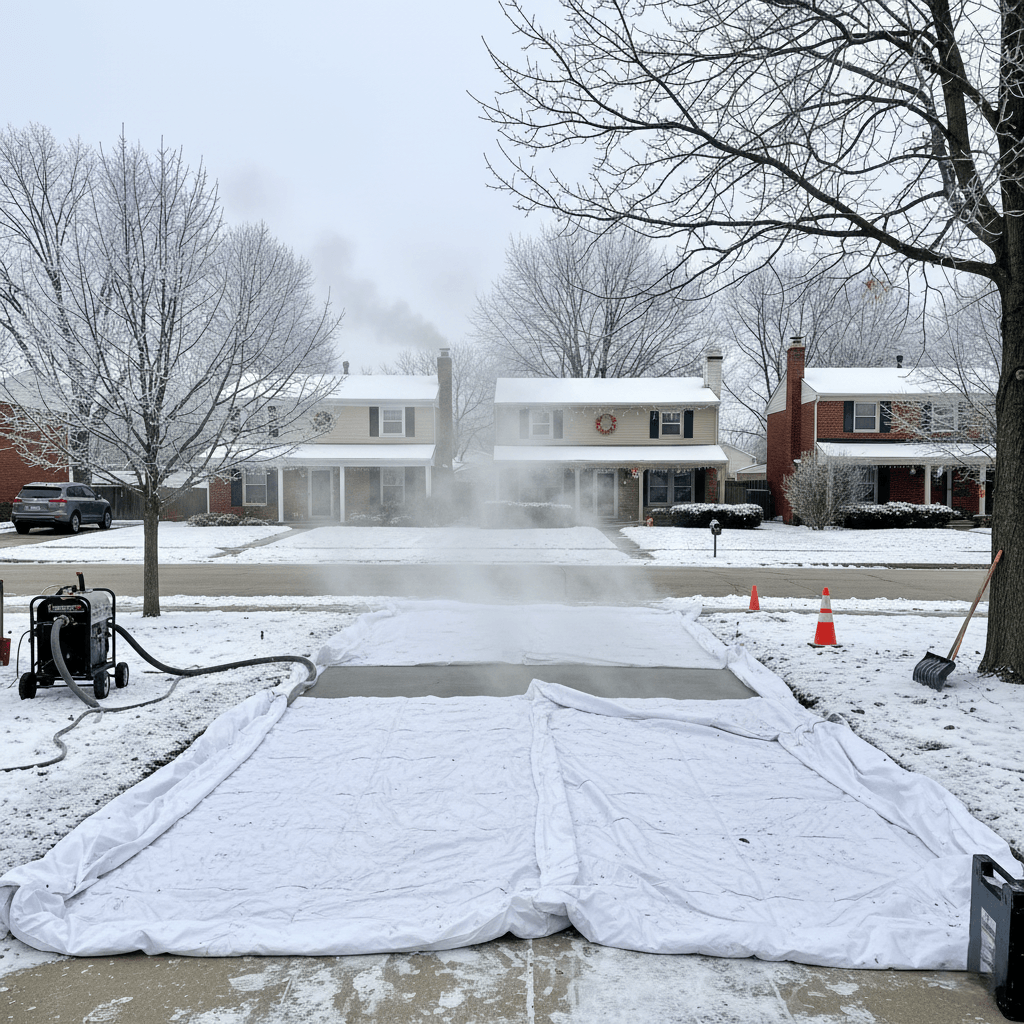

Seasonal and Weather Issues

Weather conditions in St. Louis can significantly impact the cost of a commercial concrete project. Cold-weather construction requires additional equipment and personnel to protect the concrete and facilitate the curing process. These costs can range from a few hundred to several thousand dollars, depending on the extent of the cold-weather protection measures required. In contrast, warm weather construction in St. Louis offers ideal working conditions for concrete placement and curing, although it may require the use of evaporation retardants to prevent premature surface drying. As a result, spring and fall are considered optimal construction periods for commercial concrete projects in St. Louis. Although the cost of labor and equipment may be slightly higher during peak construction periods, the advantages of working in favorable weather conditions make them preferable to winter or summer construction.

Finishing and Surface Treatments

The surface finish of the concrete will significantly impact the cost of a commercial concrete project. Broom finishes, which are suitable for exterior walkways, are relatively inexpensive and require only basic finishing tools. In contrast, smooth troweled finishes, which are typical for interior floors, require additional finishing passes and skilled finishers. Industrial floors that require precise flatness and levelness will require more advanced finishing equipment and more skilled crews. The cost of polished concrete finishes can vary from $4 to $12 per square foot, depending on the desired level of shine. Decorative finishes, including staining, stamping, and scori, can be quite expensive, but can enhance the aesthetic appeal of the finished surface for retail and hospitality clients. Protective coatings applied to the surface of the concrete will help to maintain its appearance and functionality over time. These coatings can add from $1 to $3 per square foot to the cost of the project.

Contingency Planning

Contingency planning is a fundamental part of preparing a commercial concrete estimate. Contingency allowances should be prepared to allow for any unanticipated events that may arise during the course of a project. Contingency allowances should be calculated as a percentage of the total estimated cost. Typical contingency allowances range from 5% to 10% of the total estimate cost. The actual contingency allowance should be tailored to the project specifics. More complex projects that have greater uncertainty regarding the site conditions, the design, and the sequence of the work should have a contingency allowance that is higher than 10%. Without a contingency allowance, the risk of cost overruns is increased, and the likelihood of needing additional funds to complete the project or reducing the scope of the project is increased.

Working with Professional Estimators

Preparing an accurate commercial concrete estimate is a complex task that requires experience and knowledge of the local market. Professional estimators have a broad understanding of the pricing, availability, and labor market conditions in the St. Louis region. Accurate quantity takeoffs are essential to avoiding shortages of materials that could delay a project or generate excessive waste disposal costs. Professional estimators are able to anticipate potential problems early in the estimating process, thereby reducing the likelihood of costly change orders during the construction process. By communicating clearly with designers, contractors, and clients, professional estimators can minimize miscommunications and disputes.

Partner With St. Louis Concrete Experts

At St. Louis Concrete Works, we have the expertise to prepare an accurate commercial concrete estimate and execute the project successfully. Our company is dedicated to serving the commercial concrete needs of the St. Louis metropolitan area. Our staff has extensive knowledge of the local market, including regulatory requirements and construction-related challenges in the state of Missouri. From preparing the budget to the final placement and finishing of the concrete, we strive to provide clear pricing and high-quality craftsmanship to our clients. We handle all permitting requirements for our clients, arrange for inspections, and coordinate the project to meet our clients’ schedule and budget objectives. Whether you are developing a new warehouse, retail store, or industrial facility, we can assist you with all aspects of commercial concrete construction, from estimating to completion.