Concrete Slabs in St. Louis, MO

Building Strong Foundations for Your Projects

St. Louis Concrete Works has been a trusted source for producing top-quality, precision-engineered concrete slabs that are the backbone of any construction project. We can help with everything from pouring a slab for a small shed in your backyard to a large commercial slab for your next building project. Our team is committed to delivering you a solid slab that will endure the harsh weather conditions of St. Louis. As part of this commitment, we take great care in understanding the type of soil that exists locally in the area, particularly in Missouri, where the expansive clay creates its own set of challenges. We incorporate these challenges into every pour by ensuring that the correct sub-grade compaction and vapor barrier are included to prevent movement of the slab due to settlement and damage caused by excessive moisture.

We have a two-fold approach to developing durable slabs with a focus on long-term structural integrity. First, we utilize high-strength mix designs in order to develop a strong monolithic slab that can resist the freeze-thaw cycles of the Midwest. Second, we strategically add reinforcement such as rebar or fiber mesh in order to provide additional strength to the slab. These features enable us to deliver a concrete slab that will provide years of serviceability and stability for your next construction project. This includes but is not limited to: HVAC pads and hot tub bases, as well as large garage floors, that will be level and finished to meet the load-bearing requirements of your project.

Get A Free Quote

What Are Concrete Slabs?

Concrete slabs are horizontal surfaces of solid, continuous, cast-in-place concrete. They are structural bases for several residential and commercial structures. Because they are poured as a single, continuous piece, they provide a level and incredibly strong surface that can support immense weight. They serve as:

- Building Foundations: They may be used as foundations for buildings by providing a single, uniform base that can support all the load imposed upon a building while protecting it from water/moisture present below grade.

- Durable Flooring: They may also be used as floor coverings for garages, basement floors, patio floors, etc., and as a result will provide a durable, easily maintained surface capable of handling heavy foot and/or vehicular traffic, and will allow for many different storage options such as lawn equipment, recreational vehicles, furniture, etc.

- Bases for Accessory Buildings: They may also be used as bases for small, accessory buildings such as sheds, outbuildings, etc., by keeping them level, and allowing them to be elevated off the ground so that there is no chance of long-term damage due to moisture, and warping of structural elements (wood) due to excessive moisture content.

- Subfloor Systems: They may also be used as subfloor systems for residential and commercial construction projects. They will function as a stiff base for a multitude of finish flooring materials, such as tile, hardwood, carpet, etc.

Why Choose St. Louis Concrete Works for Your Concrete Slab?

When it comes to structural concrete, precision and knowledge of the local environment are paramount. We ensure that every slab we pour is engineered to provide a stable, long-lasting surface that meets the specific demands of your property.

- Knowledge of Local Conditions: We have extensive knowledge about the soil conditions and frost lines within the city of St. Louis. To protect the slab from the upward pressure of the freezing ground, which can cause heaving and shifting, we will take into consideration the local frost depth in the design of the slab.

- Custom Design for Specific Needs: Each slab that we pour is custom-designed for the specific requirements of your project. For example, if you need a thickened edge for a heavy shed or specialized reinforcement for a workshop floor, we can tailor the design to meet the load requirements of your project.

- Use of Premium Grade Materials: We use high-grade concrete mixes that are engineered to be as durable as possible. The materials we select are for the purpose of maximizing the compressive strength of the slab so that it may carry heavy loads for many years without cracking or deteriorating.

- Adherence to Building Codes: We meet or exceed all of the local building codes with our slabs. We will take care of the technical aspects of designing the slab, such as the amount and placement of the reinforcement steel and the overall thickness of the slab. This way, you can be assured that your structure is founded upon a safe and compliant base.

- Climate Consideration: We take into account the extreme temperature changes of the St. Louis climate when designing your slab. We utilize strategic expansion joints and air-entrained concrete to allow the slab to “breathe” through the extreme hot and cold cycles of the area.

- Efficient Turnaround Time: We are able to turn around your slab quickly and efficiently while still maintaining the highest quality standards. Our experienced staff has streamlined the process of getting your slab poured and finished quickly so that your construction project stays on schedule.

Our Concrete Slab Services

We provide a full spectrum of slab solutions, from light-duty residential bases to high-performance industrial foundations. Each project is engineered with specific reinforcement and mix designs to ensure it handles its intended load without cracking or settling.

Residential Concrete Slabs

- Garage Floors: Garage floors are very long-lasting, do not stain from oils, and do not crack. Our garage floor mix has high compressive strength, so you will be able to put cars on it and lots of heavy items on it without it failing at the surface.

- Shed Foundations: We construct a permanent base for your shed with our slab foundations. The slab will keep your shed dry by keeping it off the wet ground. It also gives you a flat place to stand, which helps to keep your doors and walls straight.

- Patio Bases: We build a permanent base for your patio or deck area with our patio bases. We concentrate on getting the subgrade correct and the right amount of drainage so that your patio will remain a comfortable, puddle-free space for many years.

- Home Additions: We give you a seamless extension to your home’s foundation when we install new additions to your home. We make sure that the new addition is tied into your old house correctly with professional anchors; this way, the new addition won’t pull away from the old house.

Commercial Concrete Slabs

- Warehouse Floors: Warehouse floors are designed to take heavy loads with our commercial warehouse slabs. We finish them with special coatings and densifiers, so they can withstand forklift traffic and pallet racking day in and day out.

- Retail Slabs: Our retail slabs are made to have a smooth finish, and are perfect for a variety of different finishes such as tile, carpet, and polished concrete. They are made with high precision and provide an excellent base for flooring in retail spaces.

- Industrial Facilities: We build industrial facilities with reinforced slabs. These slabs are made thicker than normal slabs and have heavier-duty rebar grids to help them absorb vibration and hold up to the weight of large-scale industrial equipment.

- Parking Lot Bases: We build the base for your asphalt or concrete parking lot with our commercial slabs. They are built to withstand the constant motion of vehicle traffic and the elements that come with being outside all year round.

Custom Concrete Slabs

- Floating Slabs: A floating slab is a great option for smaller buildings that sit on unstable ground. These slabs will float on the ground together as one solid slab, giving the building some room to shift a little bit with the ground, without causing structural damage to the building.

- Post-Tensioned Slabs: Our post-tensioned slabs are an additional strength for those areas with difficult soil. After the slab has been poured, we tighten high-strength steel cables inside the slab. This creates a slab that is under constant compression and extremely resistant to cracking.

- Insulated Concrete Slabs: An insulated concrete slab provides you with an energy-efficient solution to your heating and cooling needs. We include a thermal barrier within the slab, which prevents heat from escaping through the ground and allows you to maintain a consistent indoor temperature.

Our Slab Process

Our approach to slab construction is rooted in precision engineering. We recognize that a slab is only as good as the ground it sits on, which is why we focus heavily on sub-grade preparation and climate-specific finishing.

- Site Evaluation: The site evaluation process allows us to determine whether the soils at the location can support the weight (load) that will be placed on the new slab. During this process, we look for evidence of expansive clay and/or poor drainage. If either of these exists, we may have to increase the thickness of the slab and/or add additional reinforcement to support the loads.

- Custom Design: After completing the site evaluation, we develop a custom design for the slab based on the customer’s specific needs. Included in the design is determining the best PSI for the concrete mix and developing a plan for placing expansion joints to accommodate the thermal movement created from the St. Louis weather.

- Site Preparation: Next, we prepare the site for construction. We grade the area to make sure it is level and then compact the soil using professional-grade compactors. Compacting removes air voids in the soil to provide a dense, non-yielding base, which eliminates settling and sinking, and therefore prevents structural cracking in the slab.

- Forms and Steel: Following preparation, we set up the formwork and add the necessary rebar (for heavy-duty load-bearing applications) or wire mesh (for broad crack control in residential slabs). Additionally, we place all of the steel into position so that it is elevated and there is no bond between the bottom of the steel and the concrete below.

- The Pour Process: Once the forms and steel are in place, we begin the pour process with the use of modern equipment to deliver a smooth and even pour. To prevent “cold joints” in the finished slab, our crew ensures that the wet edge is maintained during the entire pour process, resulting in a monolithic (one solid piece), unified slab.

- Surface Finishing: After the pour has been completed, we apply a finish to the surface of the slab. Depending upon the customer’s requirements, this finish could include a variety of textures, such as a smooth power trowel finish for a garage or a textured broom finish for an outdoor equipment pad.

- Proper Curing: The final step in the slab construction process is the curing process. In order to achieve the maximum strength and durability possible, the slab must be cured correctly. Therefore, we utilize moisture retention products to slow down the hydration of the concrete, which allows it to reach its rated compressive strength and prevents surface scaling.

Why Proper Slab Installation Matters in St. Louis

In the Gateway City, a concrete slab is more than just a flat surface; it is a structural component that must survive some of the most challenging environmental conditions in the Midwest. Because St. Louis sits in a transitional climate zone, the technical specifications of your slab can mean the difference between a lifetime of service and premature failure.

- Freeze-Thaw Cycles: The design of our slabs will help them not crack due to seasonal weather changes. In addition to having an average of over 50 freeze-thaw cycles per year in St. Louis, we also use air-entrained concrete. This type of concrete has billions of microbubbles (air pockets), which provide enough room for ice to form inside the bubbles as it freezes, so the concrete doesn’t have to pull apart at its internal bond lines.

- Soil Movement: Our design takes into consideration the expansive nature of St. Louis’ clay soils. When these soils get wet, they swell, and when they dry out during St. Louis summers, they shrink. We use a combination of heavy subgrade compaction and strategically placed reinforcement to keep your slab stable while the ground around it is moving.

- Heavy Rainfall: Proper drainage is included with every one of our slabs to help prevent standing water. By ensuring a minimum slope of 1/8” to 1/4” per foot, we can assure you that the spring rains common in Missouri are diverted away from your foundation and thus hydrostatic pressure cannot build up in the soil under your home, causing basement leaks and slab heaving.

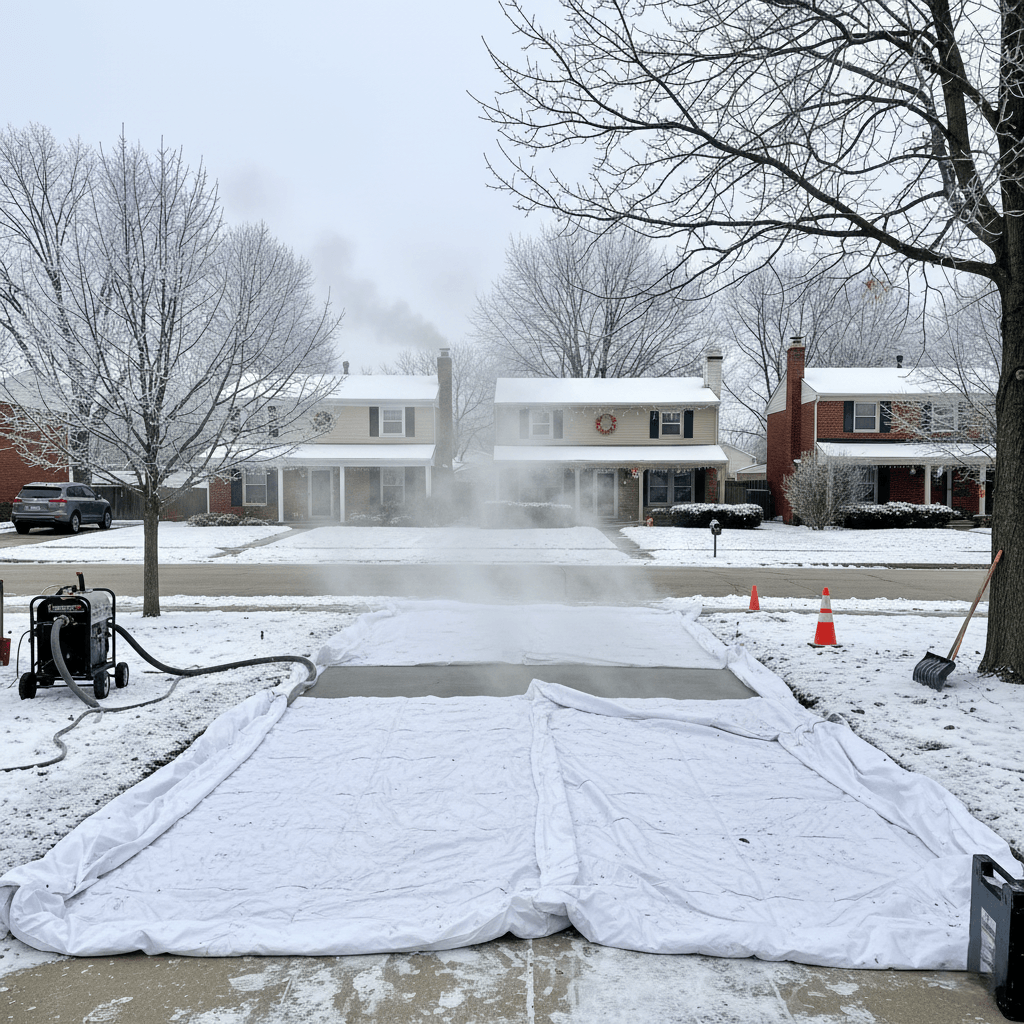

- Hot Summers: We take several measures to address extreme temperatures associated with the hot summers common in St. Louis. We use special cures and materials for our concrete mixtures, and apply moisture retention blankets to slow down the drying time of the concrete to prevent the flash set or surface crusting of the concrete that creates the spider web cracks.

Concrete Slab FAQs

Thickness varies based on the slab’s purpose. For most residential applications, 4-6 inches is standard, while commercial slabs may be 6-8 inches or more. We’ll recommend the ideal thickness for your specific project.

While concrete sets within 24-48 hours, full curing takes about 28 days. We’ll provide specific care instructions for your slab.

Yes, we can pour concrete year-round in St. Louis. We use special techniques and additives to ensure proper curing in cold weather.

Ready to Start Your Concrete Slab Project?

Whether you’re planning a new garage, shed, or commercial building, St. Louis Concrete Works is here to provide the solid foundation you need. Contact us today for a free consultation and quote. Let’s build something great together!

Get Your Free Concrete Slab Quote

St. Louis Concrete Works: Laying the Groundwork for Your Success, One Slab at a Time