St. Louis Guide: Concrete Resurfacing vs Microtopping vs Overlay

Concrete Resurfacing St. Louis

Homeowners in St. Louis who have worn-out, stained, or damaged concrete on their home will find that there are many restoration options to restore the surface of the concrete, depending on the individual needs of their situation. The difference between concrete resurfacing, microtopping, and an overlay is important to understand so you can choose the best and least expensive option for your home. In Missouri, where freezing and thawing occur frequently, along with high humidity and large changes in temperatures, selecting the correct materials for the restoration process is very important if you want a durable result. Whether you’re restoring a deteriorating driveway in Richmond Heights or upgrading a pool deck near Creve Coeur, selecting the proper method of restoration will provide you with both an improved appearance immediately as well as years of dependability.

Understanding Basic Concrete Resurfacing

Resurfacing is the addition of a thin (typically 1/8-inch to 1/4-inch) cement-based coating over an existing surface to cosmetically repair minor imperfections and refresh the appearance of the surface. While this method of repair is relatively inexpensive, it works best on structurally sound concrete with cosmetic issues such as minor cracking, surface staining, and/or weathering. To prepare the surface for resurfacing, all debris must be removed, small cracks repaired, and then the resurfacing compound applied. Many contractors in the St. Louis area offer this service on driveways, patios, pool decks, and walkways. The resurfaced layer chemically bonds to the existing concrete, forming a strong, durable surface that will withstand typical residential traffic and exposure to the elements for 8 to 15 years with proper maintenance.

Cost and Application Considerations

In the St. Louis area, in 2026, the cost for basic concrete resurfacing ranges from $3 to $7 per square foot, which is substantially less than full replacement. For example, a 500-square-foot driveway would likely cost between $1,500 and $3,500 to completely resurface, including surface preparation and sealing. Typically, labor accounts for 60% to 80% of the total cost, while materials account for the remaining 20% to 40%. Most residential resurfacing jobs can be completed in one to two days, depending on the amount of preparation needed.

In the Webster Groves and Kirkwood area, there are many residents whose homes have concrete that is still structurally sound, but has lost its appeal due to age or wear. Resurfacing offers a cost-effective way to improve the look of your home without having to replace the entire surface. Additionally, resurfacing provides opportunities to add color and texture to your concrete surfaces, greatly enhancing their aesthetic appeal, while also being very budget-friendly and quick to complete.

Microtopping: The Thin Layer Solution

Microtoppings are specialized overlay products that are applied to surfaces in very thin layers (typically 1/16-inch to 1/8-inch). Due to the thinness of the layer, microtoppings produce a very smooth, uniform surface that is perfect for interior flooring applications and some exterior applications. Once properly applied to a surface, microtoppings form a very strong bond to the substrate, providing a fresh slate for decorative treatments.

Microtoppings can be applied using a variety of tools, including trowels, squeegees, and “magic trowels,” producing a wide range of finish options from a smooth, seamless appearance to a slightly textured appearance. The versatility of microtoppings allows them to be used on a variety of substrates, including concrete, ceramic tile, vinyl composition tile, and properly prepared plywood substrates. Many properties in the Clayton and Ladue areas have used microtoppings to renovate interior floors to give them a modern, polished appearance in basements and commercial spaces.

Interior and Specialized Uses

The thin-layer nature of microtoppings makes them ideally suited for situations where a slight elevation change is undesirable, such as doorway transitions or areas with limited clearance. By preserving the original floor elevation, microtoppings allow homeowners to improve the appearance of their floors without losing headroom. The smooth, tightly troweled finish produced by microtoppings provides a great base for stains, dyes, and decorative scoring. Some installers use microtopping techniques to create a Venetian plaster appearance on vertical surfaces.

Material prices for microtoppings typically range from $2 to $4 per square foot, depending upon the desired finish and additive package. The price of installing microtoppings varies depending on the design complexity, but typically ranges from $3 to $6 per square foot. Homeowners in the University City area have successfully used microtoppings to transform outdated basement floors into attractive living spaces. Additionally, the smooth surface of microtoppings is much easier to clean and maintain than textured alternatives, which is why they are so widely used in retail spaces and high-traffic commercial applications.

Standard Overlays for Functionality and Aesthetics

Concrete overlays are the application of a thicker layer of concrete (typically 1/4-inch to several inches) over an existing surface to either repair substantial damage or provide a decorative surface. These systems are able to handle more severe damage than resurfacing and provide greater flexibility in terms of design options. Overlays are used for both functional repairs and aesthetic improvements, and can be colored, textured, and patterned to mimic a variety of natural materials, including stone, brick, and tile. The added thickness of overlays allows for more extensive stamping and textured designs. Overlay systems are particularly beneficial for exterior applications in the St. Louis area, where harsh weather conditions cause greater stress on the surface. Many properties in the Chesterfield and Ballwin areas have had success with overlays to renovate both driveways and patios.

Design Options and Performance

Stampable overlays, specifically designed for imprinting patterns onto the surface, are typically applied at a thickness of 3/8-inch to 1/2-inch, providing sufficient depth for detailed textures. Depending upon the design and materials chosen, decorative overlays can cost anywhere from $7 to $20 per square foot to install, providing homeowners with high-end appearance options at a fraction of the cost of natural materials. The added thickness of overlays also hides imperfections in the underlying surface that thinner resurfacing products cannot mask, creating a smooth, attractive surface from previously worn and damaged concrete.

Polymer-modified overlays exhibit improved flexibility and crack resistance over traditional concrete and perform well under the varying climatic conditions found in the state of Missouri. Before the application of an overlay, a suitable bonding agent must first be applied to ensure a solid bond between the new and existing surfaces. Residents of the Tower Grove Park and Lafayette Square neighborhoods have successfully utilized overlays to create dramatic visual improvements to their properties while simultaneously repairing structural damage and extending the life expectancy of the surface.

Comparison of Thickness and Material Costs

The difference in thickness among the restoration options is the main factor determining costs, capabilities, and suitability for specific applications. Minor surface wear requiring cosmetic improvements is best addressed with basic concrete resurfacing at 1/8-inch to 1/4-inch thickness. Microtoppings at 1/16-inch to 1/8-inch are ideal for applications where minimal build-up is desirable, especially in interior applications. Standard overlays, at a thickness of 1/4-inch to several inches, are used for substantial damage repairs or extensive decorative treatments. As the thickness increases, so does the quantity of material required, resulting in a corresponding increase in costs. One 40-pound bag of resurfacing compound, priced between $30 to $75, can cover approximately 120 square feet at a 1/16-inch thickness, but only 60 square feet at 1/8-inch, and 30 square feet at 1/4-inch.

Performance Characteristics of Materials

Standard resurfacing products are formulated from cement-based materials that are designed for exterior durability. Microtoppings contain polymer modifiers to enhance their workability and to produce a smoother finish. Overlay systems often include additional polymers, fibers, and other additives to enhance the strength, flexibility, and bonding qualities of the system. Colored overlays create a denser surface and provide enhanced abrasion resistance compared to uncolored concrete.

When selecting a material for a property in the South County area, it is essential to consider the specific environmental conditions, the level of traffic the surface will receive, and the aesthetic goals. Climate plays an especially significant role in testing material performance, since Missouri’s freeze-thaw cycles subject materials to annual stress. Regardless of the type of product selected, proper surface preparation is crucial for establishing a long-lasting bond between the new and existing surfaces, thereby preventing early failure and the subsequent cost of repair or replacement.

Surface Preparation Requirements

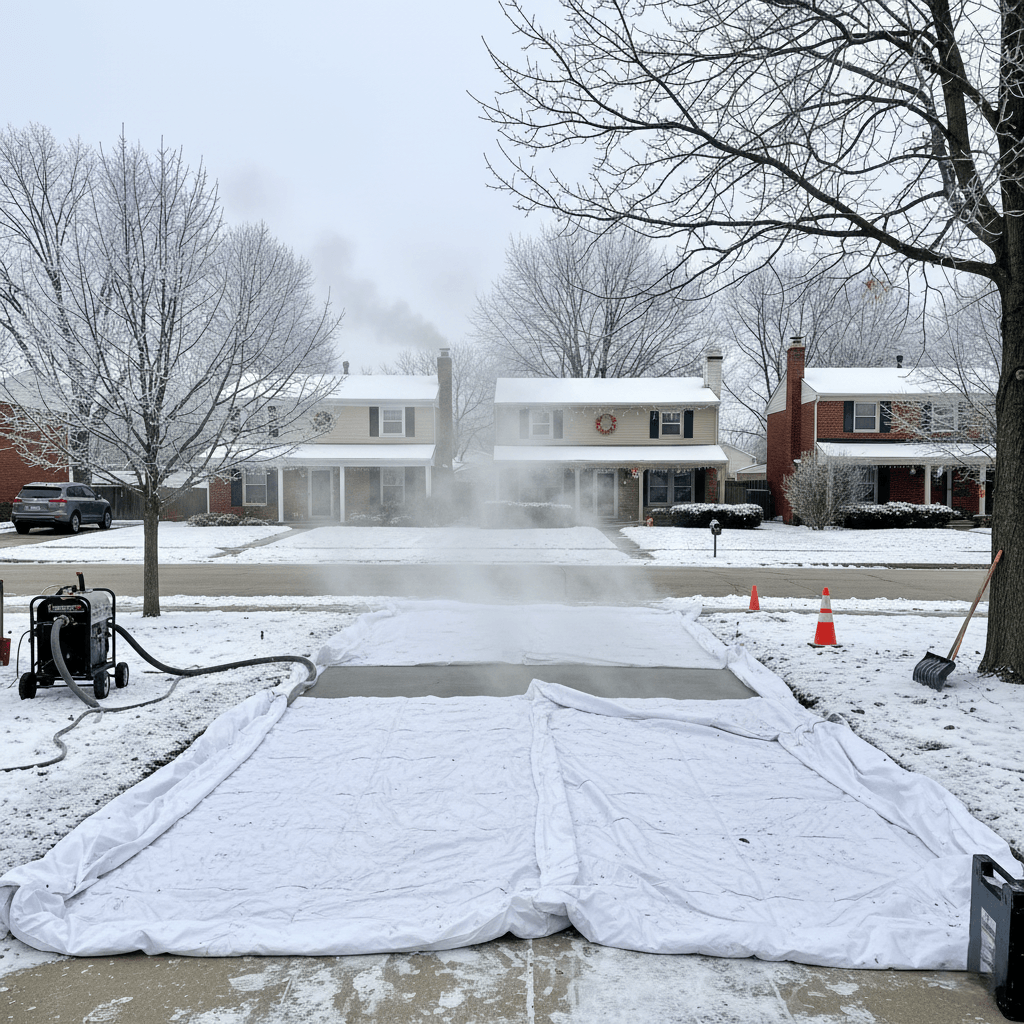

Regardless of the restoration method chosen, surface preparation is essential for successful restoration and long-term performance. All three methods begin with an aggressive cleaning of the surface to remove dirt, oil, stains, etc. Using a pressure washer accomplishes this effectively. Damaged areas of the surface must be repaired prior to the application of a new surface. Cracks in excess of 1/8-inch in width may indicate structural concerns that must be evaluated and addressed by a professional. Surface profiling (grinding, scarifying, acid etching) creates a surface texture allowing for mechanical bonding. Severely damaged or deteriorating concrete may be unsuitable for resurfacing techniques and, therefore, may require complete replacement. Before selecting a restoration approach for your property, located in the Olivette and Overland area, an honest assessment of the existing conditions is necessary to determine if an overlay solution is feasible.

Adhesion and Bonding Considerations

A bonding agent is required before applying resurfacing materials to enhance adhesion between the old and new concrete surfaces. These agents typically cost between $0.50 to $1 per square foot, and are essential for reliable performance. Moisture issues in existing slabs can negatively impact bonding, potentially leading to overlay failure via delamination. Experienced contractors assess moisture levels before completing installations. Smooth existing surfaces require profiling to create a textured surface for mechanical adhesion. Surfaces contaminated with previous sealers or coatings must be cleaned to expose clean concrete. Homeowners in the West County area can benefit from professional evaluations to identify potential adhesion issues before commencing projects. Rushing surface preparation stages to save time or money typically leads to weak bonds that fail prematurely and result in costly corrective measures.

Weather Effects on Exterior Restoration Projects in St. Louis

Missouri’s climate significantly impacts material selection and timing for exterior concrete restoration projects. Freezing and thawing cycles associated with winter months test the durability of overlay systems as moisture becomes entrapped and expands. Properly installed systems, however, resist these stresses and remain intact. Poorly installed systems will delaminate or develop cracks. Summer heat and humidity can also affect the curing process of overlays, and contractors must adjust application techniques and timing accordingly. Optimal conditions for exterior resurfacing occur during spring and fall. Whenever possible, homeowners in the Florissant and Hazelwood areas should schedule exterior resurfacing projects during non-extreme weather periods.

Long-term Performance in Local Climates

Humidity levels in St. Louis tend to support the curing of concrete, but can interfere with the application and drying of sealants. Sealant protection helps prevent the entry of moisture into the surface, thus protecting against freeze-thaw damage. Decorative overlays typically require resealing every two to three years to maintain appearance and protection. Similarly, basic resurfacing requires periodic sealing to maximize the lifespan of the surface. Chemicals associated with snow removal common in St. Louis can damage surfaces, and, therefore, sealing is essential for protection. Properties in the Affton and Lemay areas must continue to seal their surfaces to achieve optimal performance. Additionally, proper drainage design during installation eliminates standing water and ice formation, ultimately extending the life expectancy of the surface and minimizing winter maintenance tasks.

Property-Specific Factors for Choosing the Best Option

There are numerous property-specific factors that contribute to the decision-making process regarding whether to select concrete resurfacing, microtopping, or an overlay system. The condition of the existing concrete is the primary factor to be considered, as minor cosmetic issues are best suited for basic resurfacing, while more extensive damage requires the added thickness of an overlay system. Budgetary constraints also play a significant role in the decision-making process, as basic resurfacing is generally the least expensive option, and decorative overlays command a premium price. Aesthetic goals are also significant, as a simple refreshment of the surface differs from a complete visual transformation. The interior versus exterior location of the property also impacts material selection, as microtoppings are primarily used for interior applications, while overlays are used for exterior applications and must contend with the effects of weather. Homeowners in the Des Peres and Wildwood area should consult with professional contractors familiar with local conditions and project requirements to assist with their decision-making process.

Benefits of Consulting a Professional Contractor

An experienced contractor evaluates the condition of the existing surface and identifies any structural issues that resurfacing cannot address. A contractor recommends products based on the specific application and ensures that the materials selected meet the intended purpose and exposure conditions. Contractors provide homeowners with accurate estimates of the cost of their services, including preparation work, material quantities, and realistic timelines. An experienced contractor avoids costly mistakes that an inexperienced installer may commit. Contractors carrying a valid license and liability insurance protect homeowners from liability during the course of the installation.

Homeowners in the Maplewood and Brentwood area benefit from consulting with professional contractors to navigate the complexities of choosing between different material options. The warranty offered by a quality installation provides homeowners with peace of mind that a do-it-yourself project cannot match, and is a valuable justification for paying professional costs to secure superior results and long-term performance guarantees for your significant home improvement investments.

Maintenance and Longevity of Each Restoration Approach

Each of the three restoration methods requires regular maintenance to achieve maximum longevity and appearance. Regular cleaning of the surface with mild detergents and water removes dirt and debris from the surface, thereby preventing buildup. Annual or semiannual power washing keeps the appearance of the surface looking fresh and new. Periodic sealing (every two to three years) protects the surface from stains, moisture, and wear. Promptly addressing small cracks and damage in the surface prevents minor issues from developing into larger problems. Basic resurfacing typically lasts 8 to 15 years with proper care. Microtoppings in protected interior locations can last 15 to 20 years. High-quality overlays often exceed 20 to 25 years of service when properly maintained. Homeowners in the Crestwood and Sunset Hills area can maximize the value of their investments by regularly maintaining their restored surfaces according to established maintenance schedules.

Cost-effectiveness Over Time

Over time, cost comparison of the various types of concrete resurfacing will provide a great deal of insight into comparative value. A basic concrete resurfacing system can be installed on your driveway or sidewalk for $3 to $7 per square foot (this is the cost of a typical installation). In terms of longevity, this type of resurfacing has a service life of 10 to 15 years, and will cost you approximately $0.30 to $0.60 per square foot per year. An overlay system, which costs $7 to $20 per square foot in a typical installation, will last 20 to 25 years, and will cost you approximately $0.30 to $0.90 per square foot per year. Replacing all of the original surface with new concrete, in a typical installation, costs from $8 to $15 per square foot. This type of installation typically lasts 30 to 40 years and would cost you approximately $0.20 to $0.50 per square foot per year.

If your existing concrete surface is structurally sound, resurfacing it will deliver an outstanding level of value. However, if your surface is severely damaged, resurfacing may not be the best option, and in some cases, replacing your entire surface may be justified even though it may require a greater investment initially. At St. Louis Concrete Works, we assist residents within the metro area in selecting the best concrete resurfacing options based on their specific needs, budget constraints, and aesthetic desires. We then complete high-quality installations that will allow you to enjoy your outdoor space for many years while providing a beautiful appearance to your property.