Long-Term or Quick Fix? St. Louis Concrete Repair Guide

Concrete repair St. Louis

St. Louis homeowners facing damaged concrete surfaces must decide between quick temporary patches and comprehensive permanent solutions, a choice significantly affecting both immediate costs and long-term expenses. Understanding the differences between repair approaches helps property owners make informed decisions, balancing budget constraints against durability requirements. Missouri’s challenging climate with freeze-thaw cycles, expansive clay soils, and temperature extremes tests concrete repair longevity regardless of the method chosen. Properties from Kirkwood to Florissant benefit from matching repair strategies to specific damage types, intended use, and realistic maintenance expectations. Selecting appropriate concrete repair methods protects investments while avoiding repeated repairs that ultimately cost more than durable solutions implemented initially.

Understanding Quick Fix Concrete Repair Solutions

The cost of repeated, temporary repairs can be considerable in the long run. While a $30 patch kit may seem inexpensive, applying it every year for five years will total approximately $150 (plus labor), and could exceed the expense of permanent repairs that last decades. In addition to the monetary costs of repeated temporary repairs, there are also the time-related costs of maintaining an asset over time. The time spent by a homeowner on repairing an asset repeatedly can result in lost productivity and convenience.

If the repeated temporary repairs fail at inconvenient times, they will necessitate expensive “rush” services. The potential for repeated temporary repairs to cause additional damage to surrounding concrete, resulting in larger repair areas and increased professional service costs, also exists. Homeowners in University City and Richmond Heights should, therefore, compare the long-term costs of repeated temporary repairs to those associated with a single permanent solution. Additionally, because poor-quality repairs can damage adjacent concrete, the ultimate repair cost is likely to be greater than if a single, well-designed repair had been completed initially.

Long-Term, Permanent Concrete Repair Options

There are many ways to make permanent repairs to concrete. Advanced materials and established repair techniques can address the underlying cause(s) of the problem instead of simply masking the symptom. Epoxy injection provides a high-strength repair material that structurally bonds with the existing concrete to restore its load-bearing capabilities. Carbon fiber reinforcement prevents the progression of cracks while simultaneously strengthening damaged sections of concrete. Concrete leveling utilizing polyurethane foam or grout injection addresses uneven settling of the concrete that has resulted in surface problems. Full-depth repairs, which involve completely removing and replacing deteriorated portions of the concrete with new, properly-bonded material, address the weakness permanently. When investing in professional repairs for their homes, residents in Chesterfield and Ballwin enjoy the benefits of a warranty, proper surface preparation, and the use of repair materials that are specifically designed for the purpose of concrete restoration, not general-purpose patching.

State-of-the-Art Repair Materials

Recent developments in the field of concrete repair have produced new materials that exhibit improved characteristics over those used in traditional repair methods. For example, polymer-modified repair mortars provide better bonding, elasticity, and resistance to weathering than standard cement-based repair materials. Geopolymer-based repair materials provide a lower carbon footprint than conventional repair materials and exhibit greater strength and durability. Self-healing concrete, which contains bacteria or encapsulated chemicals that seal cracks automatically, offers the possibility of future applications. As homeowners in Maryland Heights and Bridgeton seek to take advantage of these advancements in repair materials and their corresponding benefits, they need to ensure that their contractor utilizes current best practices. Contractors who utilize current best practices will provide their customers with properly cured repairs that meet the specifications of the repair materials utilized.

Structural vs. Cosmetic Damage

Understanding the difference between structural and cosmetic damage will enable homeowners to select the type of repair method most suitable for the extent of the damage. Structural damage is defined as any damage that threatens the integrity of the concrete or compromises the safety of the structure. This includes such items as foundation cracks, settlement, spalling, exposed rebar, or load-bearing surface failures. All structural damage requires a professional assessment and a permanent solution, regardless of the cost. Cosmetic damage, on the other hand, refers to any damage that does not compromise the integrity of the structure or safety of the occupants. Examples of cosmetic damage include surface staining, minor hairline cracks, or shallow spalling on non-load-bearing surfaces. While cosmetic damage may be addressed with temporary repairs, such as quick fixes, it is generally recommended that structural damage receive priority funding. However, recognizing that cosmetic damage often develops into structural damage over time, homeowners should consider addressing all damage promptly to prevent the progression of damage.

Damage Evaluation and Prioritization

A thorough damage evaluation requires a structured inspection process to identify all damage and classify it according to the severity of each issue. Visually inspecting the surface of the concrete can reveal obvious damage; however, inspecting the interior of the concrete requires the use of hammers or chains to detect delamination. Measuring the width of cracks using crack gauges quantifies the degree of damage. Monitoring the changes in the size of cracks over time will indicate if the damage is progressing or remaining static. Professionals conducting damage assessments for homeowners in Wildwood and Ellisville provide a more thorough assessment of damage than homeowners may identify on their own. Structural engineers provide objective evaluations of damage, separating cosmetic issues from serious problems. Ultimately, identifying the source of the damage, whether due to poor drainage or expansive soils, is essential to developing effective repairs and preventing the recurrence of damage.

Climate Considerations for St. Louis Area Repairs

St. Louis’s climate greatly impacts the effectiveness of both repair methods and materials. Freezing and thawing cycles occur 40 to 60 times in the St. Louis area annually, and stress the interfaces of the repair materials and concrete. High temperatures and high humidity in the summer impact the curing and performance of the repair materials. The clay soils of the area expand and contract with varying moisture levels, and present ongoing stresses on the repaired concrete. Therefore, it is necessary for repair materials to be selected to withstand these climatic challenges, and for the repair materials to be applied at the optimal time. Residents in Olivette and Overland should realize that repair materials specifically designed for use in the climatic zone in which they reside will perform better than generic products. Contractors in the area who are knowledgeable regarding the local climatic conditions and select repair materials and timing accordingly will obtain the best possible results.

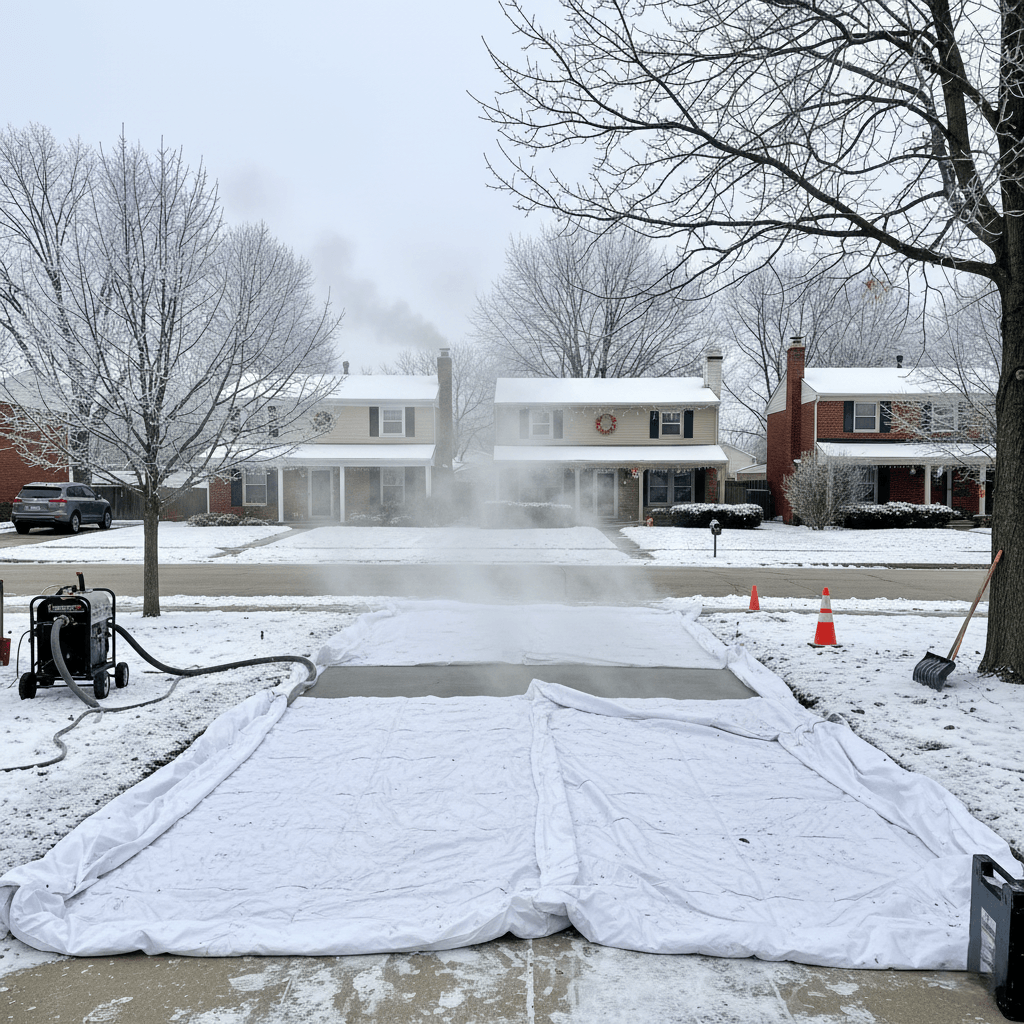

Timing of Repairs

In addition to the type of repair materials used, the timing of repairs also greatly impacts the success of the repair. In general, repairs are best performed in the spring and fall when the temperatures are mild and the humidity is moderate. Performing repairs in the summer presents heat-related challenges and requires special curing procedures to prevent premature drying of the repair materials. In contrast, performing repairs in the winter presents temperature-related challenges, as most repair materials must be applied in temperatures above freezing during the initial curing period. While some temporary repair methods can be applied under a wider range of temperatures than permanent repair methods, this advantage applies only to temporary repair methods. Regardless of the quality of the repair, poorly timed repairs are unlikely to reach the expected level of performance. Moreover, addressing concrete problems prior to winter will prevent freeze-thaw damage and worsening of the condition of the concrete during the winter months when repairs are more difficult to accomplish.

DIY vs. Professional Concrete Repair Services

Homeowners have a number of choices regarding the performance of their own repairs versus hiring a professional contractor to perform the repairs. Minor cosmetic repairs to concrete using patch kits, caulk, or sealer can be accomplished by a homeowner. The cost of materials for these types of repairs is typically between $10 and $100, although the cost of the homeowner’s time and effort should also be included in the cost of the repair. Professional contractors, on the other hand, are responsible for handling structural repairs, extensive damage, and any situation that requires specialized equipment and/or expertise. The cost of employing a professional contractor for these types of repairs can range from $500 to $5,000, depending on the complexity of the job. However, professional contractors provide many benefits that are not available to homeowners, including an accurate diagnosis of the problem, the use of materials specifically developed for the purpose of concrete repair, proper surface preparation, and a warranty for the quality of the repair. Residents in Des Peres and Town and Country who are considering the option of performing repairs themselves versus hiring a professional contractor to perform the repairs should carefully consider their individual skills, time, and the importance of the repair.

Value Provided by Professional Service Providers

Professional concrete repair contractors provide aseveralbenefits to homeowners in addition to simply installing repairs. A key benefit is the ability to accurately diagnose the problem. Not only do professional contractors have the training and experience to diagnose the problem correctly, but they also have access to the necessary testing equipment to determine the root cause of the problem. Once the root cause of the problem is identified, the professional contractor can determine the most effective repair method to address the problem. Since the contractor knows a variety of repair methods and materials, he/she can select the most efficient and cost-effective repair method for the particular problem.

The professional contractor also has access to specialized equipment that is needed to properly install certain types of repairs. For example, contractors with epoxy injection equipment can properly inject epoxy into cracks and joints to structurally reinforce the concrete. Because professional contractors know the variety of repair materials available, they can select the repair materials that are most suitable for the particular problem being addressed. Finally, since professional contractors guarantee the quality of their work, homeowners can be assured that the repairs will be done properly. Property owners in Sunset Hills and Shrewsbury who hire professional contractors to perform repairs for them will reap the benefits provided by these contractors. Additionally, since professional contractors have established relationships with the manufacturers of repair materials, they have access to the newest and most technologically advanced repair materials and techniques, and can provide homeowners with the best possible results.

Comparative Cost/Benefit Analysis for Repair Options

To determine the feasibility of using a quick fix or a permanent repair, homeowners must weigh both the initial costs of the repairs and the long-term costs. While quick fixes may appear to be economically feasible in the short term, the repeated use of quick fixes can result in substantial costs over a longer period of time. For example, while a $30 patch kit may appear to be a reasonable cost for a single repair, applying it every year for five years will total approximately $150 (plus labor), and may exceed the cost of a permanent repair that will last decades. In addition to the monetary costs of repeated temporary repairs, there are also the time-related costs of maintaining an asset over time.

The time spent by a homeowner in repairing an asset repeatedly can result in lost productivity and convenience. If the repeated temporary repairs fail at inconvenient times, they will necessitate expensive “rush” services. The potential for repeated temporary repairs to cause additional damage to surrounding concrete, resulting in larger repair areas and increased professional service costs, also exists. Homeowners in Cottleville and St. Peters should, therefore, compare the long-term costs of repeated temporary repairs to those associated with a single permanent solution. In addition, the fact that poor-quality repairs can damage adjacent concrete should be recognized, and the long-term cost implications should be considered.

Return on Investment Considerations

Concrete repairs can also provide a return on investment through several avenues beyond simply improving the appearance of the surface of the concrete. For example, repairs that improve the appearance of the concrete can increase the property values of the residence. Similarly, repairs that eliminate trip hazards can decrease the liability risk of the homeowner. Repairs that prevent water infiltration can protect the foundation of the residence and prevent costly moisture damage. Finally, well-maintained concrete can enhance the curb appeal of a residence and improve its marketability. Residents of the St. Louis metropolitan area who invest in quality concrete repairs for their residences will be protecting their real estate investments. Additionally, by addressing concrete problems early when the repairs are still relatively straightforward, homeowners can avoid emergency repairs that are often much more expensive and will also minimize the disruption to their lives.

At St. Louis Concrete Works, our goal is to assist homeowners in the St. Louis metropolitan area in determining the most cost-effective repair option for their concrete needs, and to assist them in obtaining the highest quality repairs using the most modern and cost-effective methods and materials available, and to provide them with the assurance that comes from knowing that the root causes of the problems are being addressed and that the repairs will stand up to the unique climatic challenges of the St. Louis metropolitan area.