St. Louis Polished Concrete Flooring: Pros, Costs & Trends

Concrete Flooring St. Louis

Homeowners across St. Louis are adopting polished concrete flooring due to its high level of sophistication over hardwood or tile flooring options. The durability offered by polished concrete floors provides an ideal opportunity for homeowners to create clean and contemporary spaces with design elements currently trending. Although it has become very popular among various architectural styles, from the historic Victorian homes in Lafayette Square to the new loft renovations being done downtown, all types of homes can benefit from the installation of polished concrete floors. Once installed, the plain-looking concrete slabs are transformed into shiny, mirror-like surfaces that not only improve the aesthetic quality of your home but also increase its value of your home. By learning more about polished concrete flooring, including the advantages, disadvantages, and maintenance requirements, will help you understand the possibilities of using this type of flooring as an option in your home.

The Rise in Demand for Concrete Flooring

Contractors in St. Louis report an increased number of inquiries regarding polished concrete flooring, specifically among homeowners seeking to implement organic, modern, and industrial designs within their homes. Trends in St. Louis design emphasize the use of warm, earthy materials paired with modern finishing techniques to create welcoming and sophisticated environments. Concrete flooring is a perfect complement to the exposed brick walls found in many renovated Soulard rowhouses and older structures throughout the city. Reflective surfaces created by polished concrete also contribute to increased natural light within homes, thereby creating a greater sense of space, regardless of the size of the room. Increased awareness of green building methods and environmentally friendly products has further contributed to the popularity of this sustainable flooring option among environmentally conscious St. Louis residents.

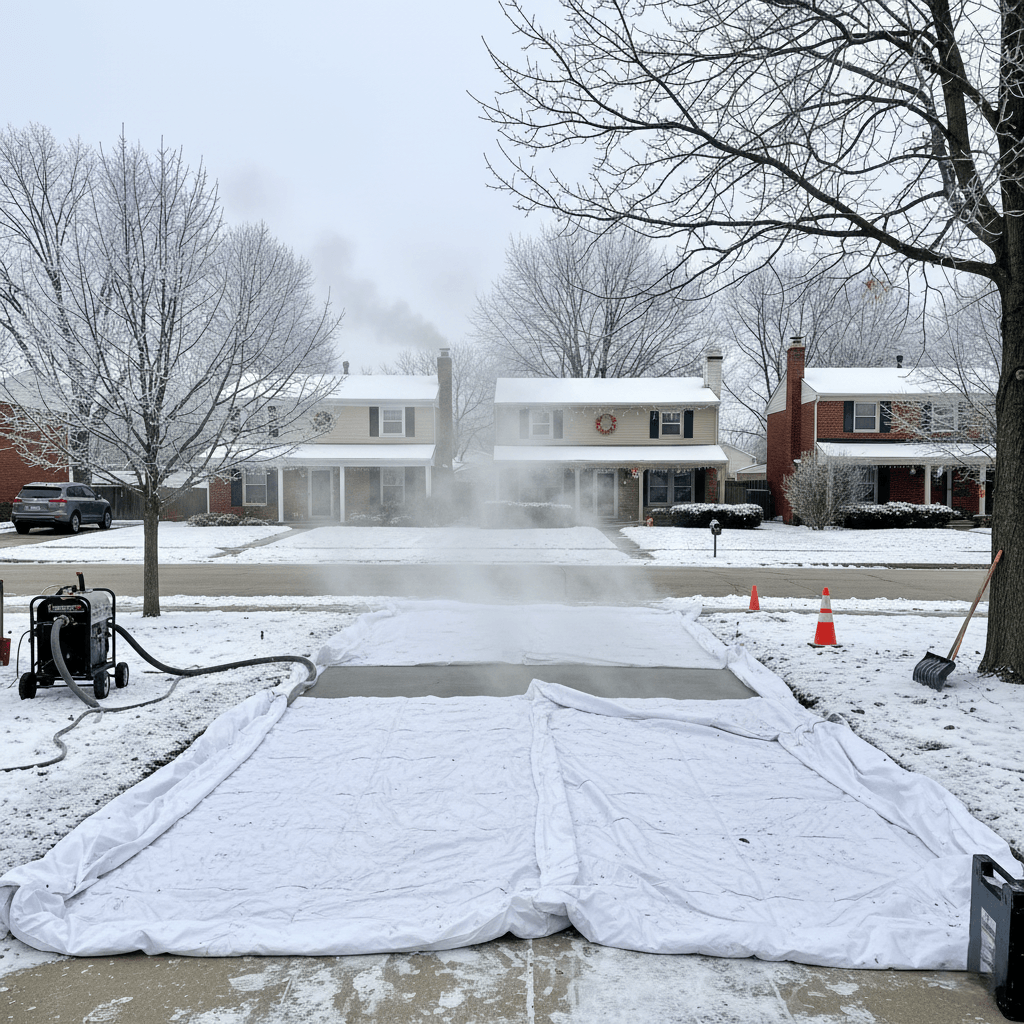

An Explanation of How the Polishing Process Works

To obtain a polished concrete floor, contractors must first grind existing concrete slabs with progressively finer abrasives (diamond) to smooth out any surface irregularities. Each abrasive used will be coarser than the previous one used, allowing the contractor to slowly refine the surface of the concrete to the desired level of sheen. The application of penetrating densifiers fills the microscopic pores within the concrete, thus preventing excess moisture from entering the concrete and increasing its strength and resistance to abrasion. The number of grinding passes will have an effect on the appearance of the finished product, and the more passes required, the more glossy the finished product will appear. Most residential polished concrete installations will require anywhere from four to eight grinding steps to produce a polished concrete floor that balances both the aesthetic appeal of the floor and the practical durability of the floor.

Finishing Levels and Customization

Homeowners may choose a variety of different finishing levels (matte, semi-gloss, high-gloss), based upon their individual design preferences and functionality requirements. Matte finish polish will provide a more subtle appearance, while still appearing sophisticated; however, it offers better traction in wet environments. Medium to medium-dark semi-gloss polish will reflect approximately 20% to 40% of ambient light, providing a good balance of visual interest and reflectivity. High-gloss polish will provide the greatest reflectivity (typically 80% to 90%), creating a dramatic “mirror-like” appearance, maximizing reflected light, and creating an interesting focal point. Decorative items such as acid staining, dye, and scoring will add visual interest and texture to the surface.

Cost Factors to Consider as a St. Louis Homeowner

Polished concrete flooring can range in price from $3 to $12 per square foot in the St. Louis area, depending upon the degree of difficulty in completing a particular project and the quality of finish desired. The least expensive method of polishing existing slabs will be during the course of either a new construction or renovation project. On-site ground-level installations are generally less expensive than on-site upper-floor installations, due to the added expense of installing waterproofing and cement underlayment to protect the polished concrete from damage from above. Any additional decorative elements (custom staining, intricate scoring, etc.) will increase the total cost of the project. However, once installed, polished concrete flooring will eliminate the need for repeated maintenance and replacement of other flooring types, and long-term savings may justify the higher upfront investment.

Comparison to Traditional Hardwood Flooring Costs and Maintenance

Hardwood flooring installations normally begin at over $10 per square foot, and do not account for any ongoing maintenance costs. Tile projects are normally three to four times more expensive than a basic polished concrete installation, and require grouting and periodic replacement. Carpeting, in addition to requiring regular cleaning and replacement every 5 to 10 years, generates numerous recurring expenses that polished concrete does not incur. Factoring in the life expectancy of a properly installed polished concrete floor, which can exceed 50 years, makes the purchase decision easier for many St. Louis homeowners. Many homeowners consider polished concrete a single investment in flooring that completely removes all future flooring replacement costs.

Long-term Durability and Life Expectancy

Polished concrete flooring can withstand much heavier foot traffic and furniture movement than most alternative flooring materials. The hardened surface of polished concrete will resist scratches, chips, and dents that occur regularly with hardwood and laminate flooring. Unlike tile flooring, which develops cracked grout lines and loose tiles over time, polished concrete remains monolithic and stable. Once properly maintained, polished concrete can remain intact for the remainder of a home’s life expectancy without requiring replacement or extensive repair. Due to its remarkable durability, polished concrete flooring is an excellent choice for high-traffic areas, including kitchens, living rooms, entryways, and other areas within homes located in St. Louis.

Cleaning and Maintenance Requirements

Daily maintenance of polished concrete floors involves little more than a simple dust mop or broom to remove dirt and debris that can scratch the surface. Damp mopping weekly with a pH-neutral cleaner will maintain the appearance of the floor without compromising the protective sealer applied to the polished concrete. Re-sealing the floor periodically (every 2 to 5 years, depending upon usage) will preserve the floor’s original luster and protective properties. Polished concrete flooring requires no waxing or refinishing and presents a low-maintenance environment compared to hardwood flooring. Small spills clean up quickly and easily with water and mild soap, and make polished concrete a good choice for households with young children and pets.

Potential Problems with Staining

Even though a properly sealed polished concrete floor is resistant to most staining agents, some substances (red wine, cooking oil, and acidic liquids) can potentially discolor the surface if allowed to sit. Allowing immediate cleanup will prevent most staining issues, and many homeowners find that the occasional marks on the surface create a unique patina. If necessary, professional cleaning services can treat any stubborn stains with specialized cleaning solutions and/or localized polishing to restore the original appearance. The lower porosity of polished concrete due to polishing and sealing greatly reduces the possibility of staining compared to an unsealed concrete surface. Routine sealer maintenance is the best way to protect against potential staining issues.

Health and Environmental Benefits

In terms of sustainability, polished concrete flooring is one of the most environmentally responsible flooring options currently available for residential use. By utilizing existing concrete slabs, there is a reduction in the need for additional materials, which decreases the amount of resources needed for the project, as well as the amount of construction waste generated. Polished concrete also utilizes very few chemicals in the manufacturing process, and modern sealers have low or zero volatile organic compounds (VOCs) that would negatively affect indoor air quality. Polished concrete provides a hypoallergenic surface compared to carpet, which harbors allergens, dust mites, and pet dander, and contributes to poor indoor air quality. Many LEED-certified projects utilize polished concrete flooring for its environmental benefits and its contributions to sustainable building practices.

Thermal Mass and Comfort

Polished concrete has the inherent ability to regulate indoor temperatures through its thermal mass. During warmer weather, the polished concrete absorbs the heat and then releases it gradually when the cooler temperatures arrive. This helps reduce energy expenditures related to heating and cooling throughout St. Louis’ varying climate conditions. Some homeowners opt to install radiant floor heating underneath the polished concrete, providing an extremely efficient and comfortable heating system. In the warmer months, the polished concrete provides a cooler surface, reducing the need for air conditioning and providing relief from the humid heat in Missouri.

Aesthetic Appeal and Design Versatility

Polished concrete flooring pairs well with a wide array of interior design themes and styles, ranging from ultra-modern minimalist to rustic industrial chic. The neutral tone of polished concrete serves as a versatile background for showcasing furniture, artwork, and architectural features. Warm brown and terracotta-colored stains can complement current design trends emphasizing earthy, organic color schemes. Additionally, polished concrete flooring provides a seamless transition between indoor and outdoor living spaces, which is particularly popular in St. Louis homes featuring patios and gardens. The reflective surface of polished concrete also increases the efficiency of lighting, making spaces appear larger and brighter regardless of the actual square footage of the room.

Common Objections and Misconceptions About Polished Concrete Flooring

Many homeowners are concerned with the hardness of polished concrete flooring, particularly regarding standing comfort and the possibility of injury resulting from falling. Strategically placed cushioned rugs in high-traffic areas (i.e., kitchen counters, workstations, etc.) alleviate fatigue concerns in those locations. Additionally, the inherent hardness of polished concrete actually provides a safer environment than softer flooring materials that can shift or buckle and create uneven walking surfaces. Surface cracking in polished concrete can develop over time, but proper installation, including adequate expansion joints, greatly minimizes the likelihood of this occurring. Contractors familiar with local soils and structural conditions are aware of the factors influencing the performance of polished concrete flooring in St. Louis homes.

Recommended Areas for Installation Within Homes

Residential polished concrete flooring projects commonly begin in basements since the slab already exists and usually only requires minor preparation. Main-level living areas, including kitchens, dining rooms, and great rooms, demonstrate polished concrete’s aesthetic flexibility while benefiting from its practical aspects. Open-concept floor plans are particularly suited for polished concrete due to its ability to create continuous, unbroken surfaces between multiple functionally separate areas. Bathrooms and laundry rooms appreciate polished concrete’s resistance to moisture and ease of cleaning. Some homeowners even extend polished concrete into bedroom areas and use area rugs to add warmth and define the bedroom zone.

Importance of Hiring an Experienced Contractor for Installation

Properly executed polished concrete flooring installations require a contractor who possesses specialized equipment, technical knowledge, and a thorough understanding of concrete characteristics. Residential polished concrete flooring installations are subject to higher standards than commercial installations, and homeowners expect flawless finishes and consistent coloration. Before commencing the polishing process, an experienced contractor will evaluate the condition of the existing slab, identify possible problem areas, and recommend suitable preparation procedures. Proper moisture testing will ensure that coatings adhere properly, and the polished surface will remain intact for its intended life expectancy. Certified and licensed contractors also possess liability insurance to protect homeowners from potential installation errors and to ensure compliance with local building codes.

How to Select the Best Contractor for Your Project

When searching for a contractor to perform a residential polished concrete flooring installation, seek contractors who have prior experience in performing residential polished concrete flooring installations, rather than strictly commercial applications. Examine the photographs of previously completed projects displayed in the contractor’s portfolio that are similar to your desired aesthetic and finish quality. Ask previous customers for referrals and ask them about the longevity and performance of the installed polished concrete flooring. Written detailed estimates provided by contractors should describe the finish level, type of sealer to be utilized, number of grinding passes, and any decorative treatments included. Professional contractors will provide realistic timelines, explain the installation process in detail, and answer any questions you may have before commencing work.

Converting Your Home with Polished Concrete Flooring

Polished concrete flooring provides St. Louis homeowners with the ultimate combination of style, durability, and value that few other flooring materials can duplicate. Regardless of whether you are renovating a historic Victorian-style home in Lafayette Square or modernizing a suburban ranch home, polished concrete flooring is a flexible and adaptable flooring solution that can be incorporated into almost any architectural context. At St. Louis Concrete Works, we specialize in residential polished concrete flooring installations that transform dull, plain concrete slabs into beautiful design features. Our experienced staff assesses your specific needs, suggests finish and treatment options, and completes the installation with precise attention to detail. We understand the unique integration of polished concrete with St. Louis’ varied housing stock and design preferences, and our goal is to consistently meet or exceed client expectations while adhering to budgetary constraints and project timetables.